جدول المحتويات

تبديلCutting metal can feel like a hard job, but with the right tools, it becomes much easier. One of the most useful tools for this task is the angle grinder. People use it to cut through steel, iron, and other metals quickly. It is popular because it can handle many different jobs, from small home repairs to bigger projects.

In this guide, you will learn how to pick the right angle grinder disc for cutting steel. You will also learn how to use it safely and how to avoid common mistakes. We will go step by step so that you can follow along, even if you are new to using power tools. By the end, you will know how to make clean cuts, protect yourself, and get the best results when working with metal.

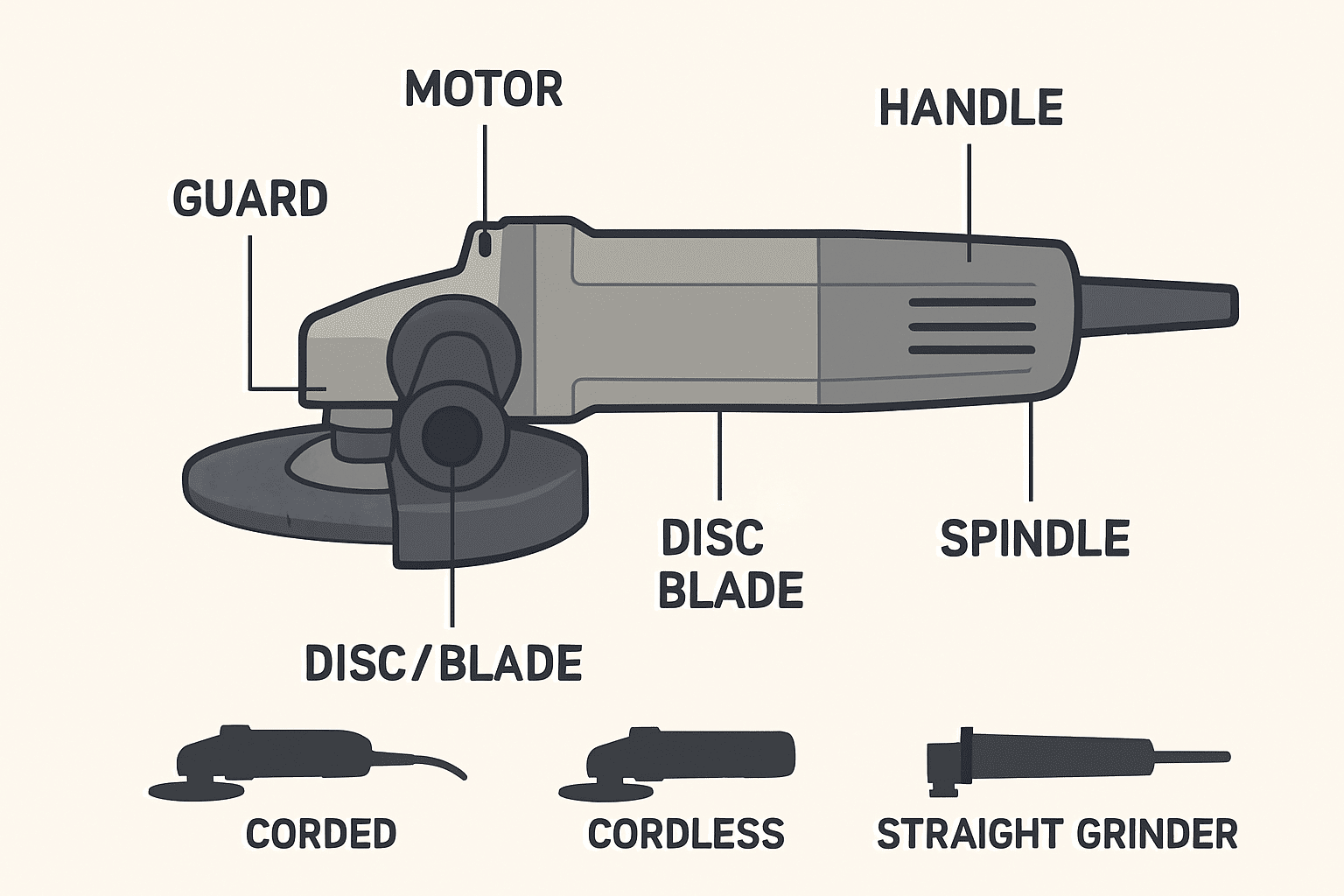

Understanding the Angle Grinder and Its Components

أ طاحونة زاوية is a handheld power tool that people often use to cut and shape metal. It works with a fast-spinning motor that drives a disc. The tool is small enough to hold in your hands, but it is powerful enough to cut steel, grind surfaces, or even polish edges.

Main Parts of an Angle Grinder

The angle grinder is made up of several important parts:

- Motor: Located inside the body, it makes the disc spin at high speed.

- مقبض: Gives you a strong and steady grip while working.

- يحمي: A safety cover that blocks sparks and small pieces of metal from flying toward you.

- Disc or Blade: The cutting or grinding part that makes contact with the metal.

- مغزل: The connector that holds the disc firmly in place and links it to the motor.

Corded Angle Grinders

Corded angle grinders plug into an electrical outlet. They deliver steady, strong power, which makes them suitable for longer or heavier jobs. Since they do not rely on batteries, you can use them for continuous work without worrying about running out of charge. The only drawback is that the cord limits movement and may get in the way in tight spaces.

Cordless Angle Grinders

Cordless angle grinders run on rechargeable batteries. They are portable and easy to carry, making them perfect for outdoor work or jobs far from a power source. You do not need to worry about managing a power cord. However, the battery limits the running time, so they are better for smaller or medium-sized tasks rather than long, heavy-duty jobs.

Straight Grinders

Straight grinders look different from standard angle grinders. They have a longer, slimmer body with the disc mounted in line with the motor. This design makes them useful for detailed work, polishing, or grinding in narrow spaces. They are not as powerful as large angle grinders, but they offer better control for precision tasks.

Choosing the Right Disc or Blade for Cutting Metal

The disc or blade you use on your angle grinder makes a big difference in performance and safety. Each type of disc has a specific purpose, and using the wrong one can make the job harder or even unsafe.

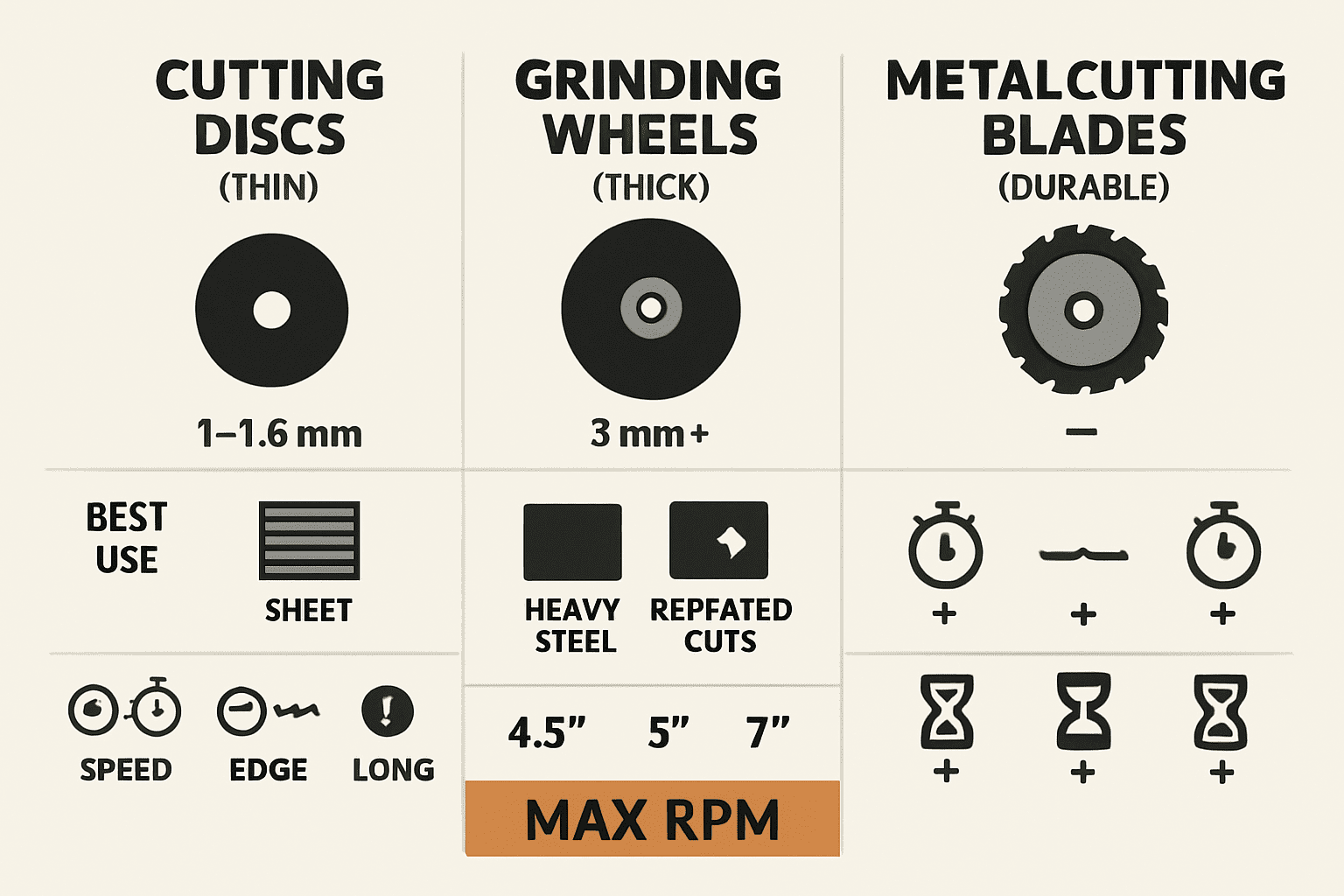

Cutting Discs for Metal

Cutting discs are thin and sharp. They are designed to slice cleanly through steel and other metals. Thin discs cut quickly and leave smoother edges, while thicker discs last longer and handle tougher materials.

Grinding Wheels

Grinding wheels are thicker and stronger than cutting discs. Instead of slicing through metal, they are made to grind down surfaces, smooth rough edges, or remove extra material. If you try to cut with a grinding wheel, it will be slow, rough, and unsafe.

Metal Cutting Blades

Metal cutting blades are built for tougher jobs. They can handle heavy-duty steel and are made from stronger materials for longer life. These blades are often used when you need durability and repeated use.

Disc Sizes and Safety Ratings

Discs come in several common sizes, such as 4.5-inch, 5-inch, and 7-inch. Smaller discs are easier to control and better for light work. Larger discs can cut deeper and faster but feel harder to handle. Every disc has a maximum RPM rating. Always check that the speed of your grinder does not go above this number.

Choosing the right disc helps you cut faster, stay safe, and get cleaner results.

Cutting Disc Specifications Explained

Before you start cutting metal, it is important to understand the specifications of the cutting disc. These details tell you how the disc will perform and how safe it is to use.

Disc Thickness and Application

The thickness of a cutting disc affects both speed and control. Thin discs, such as 1 mm or 1.6 mm, cut quickly and leave a clean edge. They are best for sheet metal and small steel parts. Thicker discs, such as 3 mm or more, are stronger and last longer. They work better for cutting through solid bars or heavy steel. If you use a disc that is too thick for thin material, it may create too much heat and damage the surface.

Grit Values and Selection

Cutting discs often show a GRIT value. This number tells you how rough or smooth the cutting surface is. Lower numbers mean a coarser surface, which removes material faster but leaves a rougher cut. Higher numbers mean a finer surface, which cuts more slowly but gives a smoother edge. For most steel cutting, medium grit values offer the best balance.

Disc materials: Advantages and Disadvantage

Discs are made from different materials. Aluminum oxide is common and works well for general steel cutting. Silicon carbide is sharper and cuts faster, but it can wear down quickly. Diamond discs are very strong and last the longest. They are excellent for tough materials but cost more than standard discs. Choosing the right material depends on how often you cut and what type of steel you work with.

RPM Requirements and Safe Use

Every disc has a maximum RPM (revolutions per minute). This number shows the highest speed the disc can safely spin. If your angle grinder spins faster than the disc’s rating, the disc may break apart during use. Always check the RPM marked on the disc and match it to your grinder. Using a disc within the safe speed range helps prevent accidents and ensures better performance.

By learning these specifications, you can pick a cutting disc that matches your job, keeps you safe, and gives you better results.

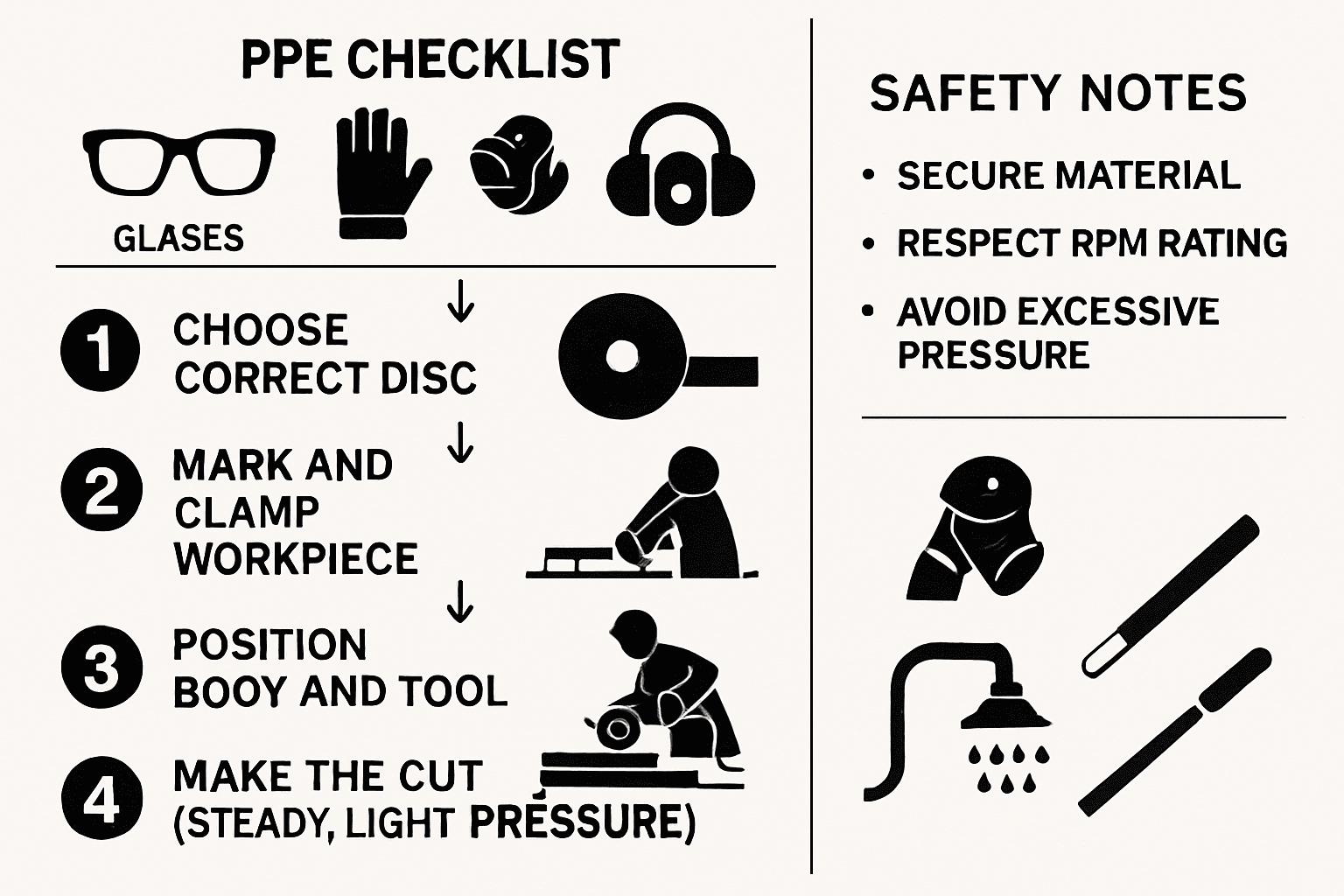

Safety Precautions Before Cutting Metal

Safety should always come first when using an angle grinder. The tool is powerful, and if you use it without care, it can cause accidents. Following a few safety steps will help you cut metal without risk.

- Wear personal protective equipment (PPE). Always use safety glasses or goggles to protect your eyes from sparks and small pieces of metal. Gloves will keep your hands safe from sharp edges. Ear protection reduces noise damage, and a respirator or mask helps you avoid breathing in metal dust.

- Secure the workpiece. Never try to hold the metal in your hands while cutting. Use a clamp or a bench vise to keep it steady. A moving workpiece can cause the disc to slip, which is dangerous.

- Inspect your grinder and discs. Before starting, check that the grinder is in good condition. Look for cracks or damage on the cutting disc. Do not use a disc that looks worn out or broken.

- Prevent kickback and sparks. Hold the grinder firmly with both hands and cut at a steady pace. Do not push too hard. Let the disc do the cutting. Stand to the side when possible so sparks do not fly toward you.

By following these steps, you can cut steel safely while keeping control of your tool.

Step-by-Step Guide to Cutting Metal With an Angle Grinder

Cutting metal with an angle grinder is not difficult if you follow the right steps. Taking your time and working carefully will give you clean and safe results.

Step 1: Choose the correct blade or disc.

Pick a cutting disc that matches the type of metal and thickness you are working with. A thin disc is good for sheets, while a thicker one works better for heavy steel.

Step 2: Mark and secure the metal.

Use a marker, chalk, or scribe to draw the line where you want to cut. Clamp the metal firmly to a bench or use a vise. A stable workpiece helps you stay accurate and safe.

Step 3: Position yourself and the grinder.

Hold the grinder with both hands. Stand slightly to the side instead of directly behind the disc. This way, sparks and debris are less likely to hit you.

Step 4: Make the cut.

Switch on the grinder and let it reach full speed before touching the metal. Guide the disc along the marked line with steady movement and light pressure. Do not force the cut. Let the disc do the work.

Step 5: Finish the cut and cool the blade.

When you reach the end of the cut, ease off slowly. Give the disc time to cool by pausing between cuts. If the metal edge feels rough, you can smooth it with a grinding or sanding disc.

Tips for different cuts

- For metal sheets, use a thin disc to reduce heat and avoid bending.

- For angle iron, cut through one side at a time instead of pushing through the joint.

- For steel pipes, rotate the pipe slightly as you cut for a cleaner finish.

When you follow these steps, cutting steel becomes a smooth process that delivers accurate results.

الأخطاء الشائعة وكيفية تجنبها

Even with the right tool, people often make mistakes when cutting metal. These errors can damage the disc, slow the job, or even cause injury. Knowing what to avoid will save you time and keep you safe.

- Using the wrong blade type. Some people use a grinding wheel to cut metal, but this is not safe. Grinding wheels are too thick and not made for cutting. Always choose a disc designed for cutting metal.

- Applying too much pressure. It may feel faster to push the grinder hard into the metal, but this puts stress on the disc and the motor. Too much pressure can make the disc break. Use light, steady pressure and let the disc cut at its own speed.

- Cutting without securing the material. If the metal moves while you cut, the grinder can slip. This may ruin the cut or hurt you. Always clamp the metal before starting.

- Ignoring RPM limits. Every disc has a speed rating. If your grinder spins faster than the disc allows, the disc may break apart. Always check the RPM rating on the disc and make sure it matches your tool.

Avoiding these errors saves time, prevents accidents, and helps you cut metal with confidence.

Material-Specific Cutting Techniques

Different metals need different cutting methods. Using the same technique for every type of material can cause poor results or damage. Below are some simple tips for cutting common materials with an angle grinder.

Stainless Steel

Stainless steel is tough and generates a lot of heat during cutting. Too much heat can discolor the surface and weaken the metal. To avoid this, use a thin cutting disc that creates less friction. Cut in short passes instead of one long push to control heat. Allow the disc to cool between cuts. You can also place a damp cloth near the cutting area to absorb some of the heat. Keep your pressure light and steady to prevent sparks from building up in one spot.

Thin Metal Sheets

Thin sheets bend easily under pressure, so you must be gentle when cutting. A thin cutting disc works best because it removes less material. Secure the sheet tightly with clamps on a flat surface to stop it from moving. Avoid pressing down too hard, as this can warp the metal. Move the grinder smoothly along the cutting line. If possible, cut with the sheet supported on both sides so the metal does not sag or twist while you work.

Carbide Steel

Carbide steel is very hard, which makes it more difficult to cut. Use a stronger cutting disc, such as one with diamond edges, for better results. Work slowly and let the disc do most of the effort. Take breaks if needed to keep the tool cool. Trying to rush through carbide steel can wear down your disc quickly or even break it. Always wear strong protective gear because sparks and debris are heavier with this type of metal.

Aluminum

Aluminum is softer than steel, but it can clog the disc. When the disc clogs, it overheats and becomes unsafe. To prevent this, use a disc made for non-ferrous metals. Apply only light pressure and keep the grinder moving. You can also rub candle wax or cutting lubricant on the disc before cutting. This helps reduce clogging and keeps the cut smooth.

Precision and Special Techniques

For jobs that require clean edges or exact measurements, use a thin disc with high grit. Mark your line carefully with a ruler or straight edge. Move the grinder slowly and keep your hand steady. For very detailed cuts, practice on scrap metal first. Some workers also use jigs or guides to keep their cuts straight. Precision work takes patience, so always cut slowly and carefully.

Maintenance of Your Grinder and Blades

Taking care of your angle grinder and blades will make them last longer and work better. A well-maintained tool is also safer to use. Regular care does not take much time but makes a big difference.

- Clean the tool after use. After cutting, dust and small metal shavings can collect inside the grinder. Use a brush or air blower to clear away dirt. Wipe down the outside with a dry cloth to keep it clean.

- Store discs properly. Cutting discs should be stored in a dry place. Keep them flat and away from moisture to stop them from bending or cracking. Do not leave them in the sun or near heat sources because that can weaken them.

- Check for wear and cracks. Before every job, look at your discs closely. A disc with chips, cracks, or uneven edges should not be used. Also, check the guard and handle of the grinder to make sure they are secure.

- Replace worn-out discs. Discs do not last forever. If you notice slower cutting, more sparks, or uneven edges, it may be time to replace the disc. Using an old or damaged disc can be unsafe.

Regular care keeps your grinder reliable and ready for the next project.

When to Use Alternative Tools for Cutting Metal

An angle grinder is useful for many jobs, but sometimes it is not the best tool. In certain cases, other tools can give you faster, safer, or more precise results. Knowing when to switch tools will make your work easier.

- Bandsaw. A metal bandsaw is great for straight cuts, especially on thick bars or large pieces of steel. It cuts more slowly than a grinder, but it leaves a smooth edge and makes less noise and sparks.

- Plasma cutter. If you need to cut through very thick steel or make detailed shapes, a plasma cutter is a strong option. It uses heat to melt through metal and can handle jobs that grinders struggle with. However, it is more expensive and requires practice.

- Cut-off saw. Also called a chop saw, this tool works well for cutting pipes, rods, or angle iron. It is larger and less portable than a grinder, but it provides clean, straight cuts quickly.

- Cordless grinders. In some cases, a cordless angle grinder may be the better choice. It is lighter and easier to carry, making it useful for outdoor work or jobs away from a power outlet.

Knowing when to switch tools allows you to work smarter and get the best finish on your cuts.

خاتمة

Cutting metal with an angle grinder may seem challenging at first, but it becomes simple once you know the right steps. By choosing the correct disc, following safety rules, and using proper techniques, you can make clean and precise cuts every time. Understanding disc specifications and material-specific methods also helps you match the tool to the job, which improves both safety and results.

Taking care of your grinder and blades ensures that they last longer and perform better. In some cases, using other tools like a bandsaw or plasma cutter may be a smarter choice. The key is knowing what tool works best for your task.

For dependable results, MaxXT provides a complete range of grinders, discs, and accessories designed with these principles in mind, helping both professionals and DIY users cut steel safely, efficiently, and with confidence.

FAQs About Choosing the Right Angle Grinder Disc for Cutting Steel

1. What type of angle grinder disc should I use to cut steel?

Use thin discs (1–1.6 mm) for sheet metal and thicker discs (3 mm+) for heavy steel.

2. How do I know if my cutting disc is safe?

Check the RPM rating on the disc and ensure it matches your grinder’s speed.

3. What safety gear should I wear?

Wear safety glasses, gloves, ear protection, and a mask, and always secure the metal.

4. What mistakes should I avoid?

Avoid using grinding wheels for cutting, applying too much pressure, cutting unsecured metal, and ignoring RPM limits.

5. Can I cut all metals with an angle grinder?

Yes, but use the right disc and method: thin discs for stainless/thin sheets, diamond discs for hard steel, and non-ferrous discs for aluminum.