Table of Contents

ToggleAngle grinders are one of the most useful power tools you can own. They are used in construction, metalwork, and even simple home projects. With the right disc, you can cut through concrete, steel, or tiles. You can also use them for grinding, polishing, and removing rust or old paint.

Because angle grinders can do so many jobs, choosing the right one can feel confusing. There are many sizes, power options, and disc types available. Professionals often look for strong tools that can handle heavy work. DIY users may want smaller, lighter tools that are easy to carry and use.

This guide will help you understand the important features of angle grinders. It will show you how to compare sizes, power types, prices, and safety tips. By the end, you will know how to choose the best angle grinder for your needs in 2025.

What Is an Angle Grinder and How Does It Work?

An angle grinder is a handheld power tool that uses a fast-spinning disc to cut, grind, or polish different materials. It is popular in construction sites, workshops, and even for small home repairs because it can handle many jobs with only a change of disc.

The main parts of an angle grinder are easy to understand. The motor gives power to the tool and makes the disc spin at high speed. The disc or blade is the part that touches the material and does the cutting or grinding. The guard is a safety cover that protects you from sparks and flying debris. The handle gives you a steady grip, and the spindle holds the disc securely in place.

Types of Angle Grinders

- Corded grinders plug into electricity. They deliver steady power for long tasks but limit movement because of the cord.

- Cordless grinders run on rechargeable batteries. They are easy to carry and use outdoors, but the battery limits how long you can work.

- Straight grinders have a longer body shape with the disc in line with the motor. They are best for detailed work and jobs in tight spaces.

Angle Grinder Sizes

Angle grinders come in different sizes. A 4-inch grinder is small, light, and easy to control. A 5-inch or 7-inch grinder is stronger and can cut deeper, but it feels heavier. For big projects, workers may use a large industrial grinder, while for light tasks a mini cordless grinder is often enough.

Knowing how an angle grinder works and the types available will help you choose the right one for your job.

Key Uses of an Angle Grinder

An angle grinder is a very flexible tool. It can do many different jobs depending on the type of disc you use. This makes it useful for professionals and DIY users alike.

Cutting Concrete

One of the most common uses is cutting concrete with an angle grinder. With the right blade, you can cut bricks, paving stones, or concrete blocks. This is very helpful in construction or when doing home repairs.

Cutting Metal

Angle grinders are also widely used for cutting metal. They can slice through steel pipes, iron bars, and sheet metal. Using a thin cutting disc gives you faster and cleaner cuts.

Tile Cutting

With a diamond blade, an angle grinder can cut through ceramic tiles or stone tiles. This makes it a handy tool for flooring projects or bathroom installations.

Grinding and Surface Prep

Besides cutting, an angle grinder can grind surfaces smoothly. It can remove rough edges, polish stone, or take off rust and old paint from metal surfaces. A strip disc or grinding wheel is usually used for this purpose.

Masonry and Stone Work

Masonry blades allow you to cut stone or bricks. This is useful in both outdoor landscaping and building projects.

An angle grinder’s many uses make it a must-have tool for anyone working with metal, stone, or concrete.

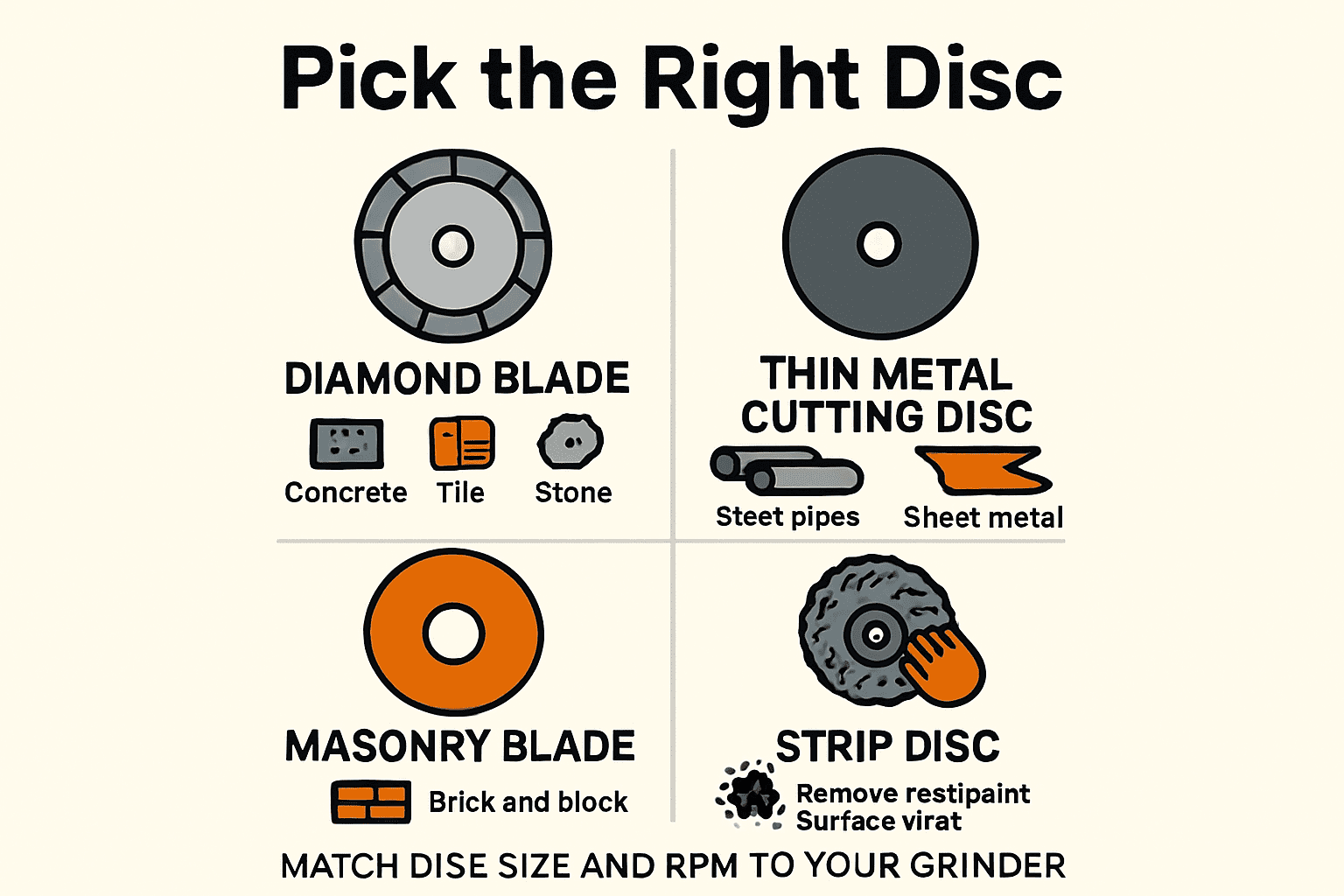

Types of Angle Grinder Discs and Blades

The type of disc or blade you choose decides what job your angle grinder can do. Each disc has its own purpose, and using the right one makes your work easier and safer.

Metal Cutting Discs

Metal cutting discs are thin and sharp. They are designed to slice through steel, iron, and other metals quickly. Thin discs give cleaner cuts but wear out faster, while thicker discs last longer and are better for heavy-duty cutting.

Concrete Grinder Discs and Blades

To cut concrete with an angle grinder, you need a strong disc. Concrete blades, often with diamond edges, can handle the hardness of stone, bricks, and concrete blocks. They are more expensive than standard discs but last much longer.

Masonry Blades

Masonry blades are made to cut stone, bricks, or blocks. They are stronger than basic metal discs and can handle the rough texture of masonry. These blades are often used in construction and landscaping projects.

Strip Discs

Strip discs are not for cutting. Instead, they are used to remove paint, rust, or coatings from metal. They prepare the surface for welding, painting, or polishing.

Compatibility and Safety

Always match the disc to the size of your grinder. For example, a 4-inch disc fits a 4-inch grinder and cannot be safely used on a 7-inch grinder. Check the RPM rating on both the disc and the grinder. If the grinder spins faster than the disc’s maximum speed, the disc could break.

Choosing the right disc improves performance, saves time, and keeps you safe during your work.

Angle Grinder Specifications

Before buying an angle grinder, it is important to understand the technical specifications. These numbers tell you how powerful the tool is, how fast it works, and what kind of jobs it can handle.

Speed (RPM)

RPM means revolutions per minute, which shows how fast the disc spins. A higher RPM means the disc spins faster, which allows for quicker cuts. However, very high speeds can also make the tool harder to control. Most small grinders run between 5,000 and 11,000 RPM. For light jobs like polishing or cutting thin sheet metal, a lower RPM works fine. For harder jobs like cutting concrete or thick steel, higher RPM gives more cutting power. Always match the disc’s rated RPM with the grinder to avoid safety risks.

Voltage

Voltage tells you how much electrical power the grinder uses. Corded grinders usually run on standard household voltage (110V or 220V, depending on your country). Cordless grinders use batteries that are measured in volts, usually between 18V and 60V. A higher-voltage cordless grinder delivers more power and can cut thicker material, but it also makes the tool heavier. For DIY projects, a lower-voltage cordless model may be enough, while professionals often prefer higher-voltage tools for tough work.

Power (Wattage)

Power, measured in watts, shows the grinder’s overall strength. Entry-level grinders may start around 500–700 watts, while professional models can reach 2,000 watts or more. More wattage means the tool can handle longer use without overheating and can cut thicker or tougher materials with ease. Lower wattage grinders are lighter and cheaper but may struggle with heavy-duty tasks.

How These Specs Affect the User Experience

If you are a DIY user, you might prefer a lighter, mid-range grinder with moderate RPM, lower wattage, and standard voltage. It will be easier to handle and cost less. If you are a professional, higher wattage, higher RPM, and strong voltage options make the job faster and safer when working with concrete, rebar, or heavy steel. The right balance of speed, power, and voltage makes a grinder both efficient and safe for your needs.

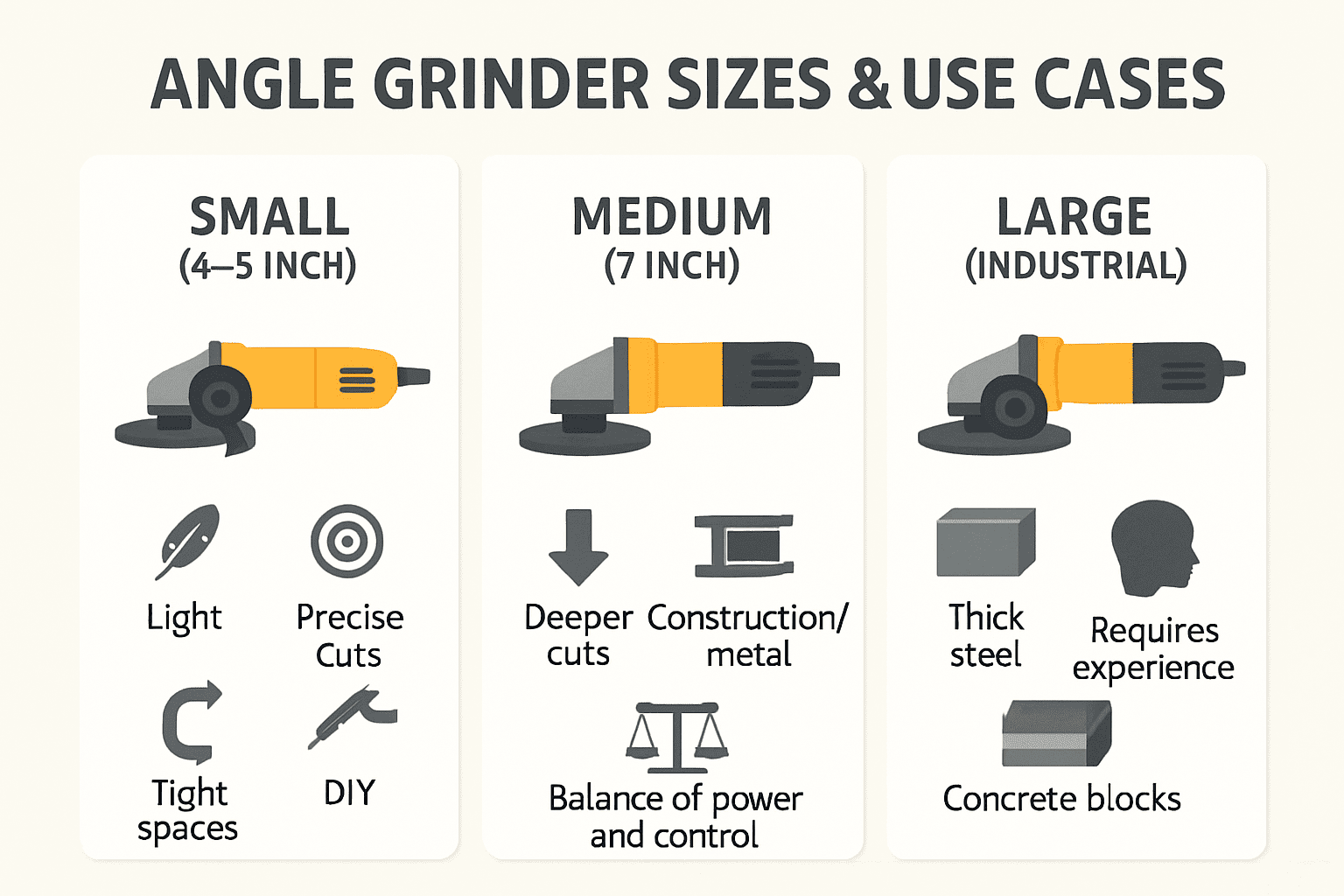

How to Choose the Right Angle Grinder Size

Angle grinders come in different sizes, and each size is better for certain types of work. Picking the right size helps you finish your job faster and with less effort.

Small Angle Grinders (4-inch to 5-inch)

A small angle grinder is light and easy to control. A 4-inch grinder is perfect for cutting thin metal, trimming bolts, or small DIY projects. A 5-inch grinder gives a little more cutting depth but is still easy to handle. These sizes are portable and work well in tight spaces.

Medium Angle Grinders (7-inch)

A 7-inch angle grinder is stronger and can cut deeper than smaller models. It is good for construction work, heavy metal cutting, or concrete jobs. Because it is heavier, it requires more control, but it gets through tough material faster.

Large Angle Grinders

A big angle grinder is used for industrial jobs. It can cut through thick steel, large concrete blocks, and heavy masonry. These grinders are powerful but also heavy, so they are not ideal for beginners or light tasks.

Mini Cordless Grinders

A mini cordless grinder is small and battery powered. It is best for quick, light jobs where portability is important. While not as powerful as corded grinders, they are useful for on-the-go tasks.

Choosing the Right Size

Small grinders are best for light, precise work. Medium grinders balance power and control for most construction tasks. Large grinders handle the heaviest jobs but require experience to use safely.

Picking the right size ensures that your grinder matches the demands of your project.

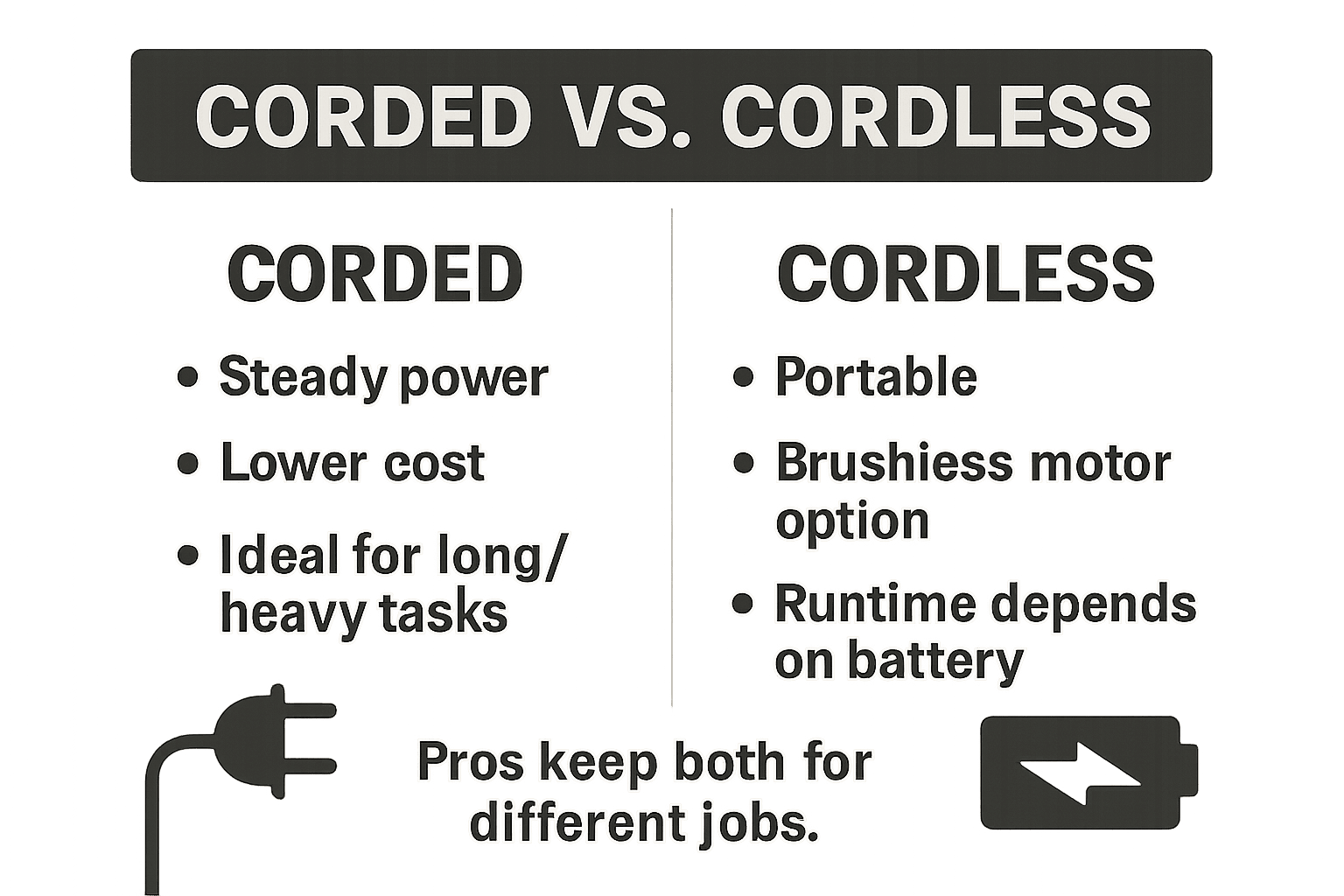

Corded vs. Cordless: Which One’s Right for You?

When buying an angle grinder, one of the first choices is whether to go for a corded or cordless angle grinder. Each option has its own strengths and limits.

Corded Angle Grinders

Corded grinders plug into a power source. They give you steady power without worrying about battery life. This makes them ideal for long projects, heavy cutting, or grinding tasks that require constant strength. Corded models also tend to be less expensive than cordless ones. The main drawback is that you always need an outlet nearby, and the cord can sometimes get in the way.

Cordless Angle Grinders

Cordless grinders run on rechargeable batteries. They are portable and can be used anywhere, even where electricity is not available. This makes them perfect for outdoor jobs, quick repairs, or places with limited access. Many cordless models now use brushless motors, which are more efficient, give longer battery life, and require less maintenance. However, cordless grinders are usually more costly, and their runtime depends on the battery size.

Which One Should You Choose?

If you need constant power for long, heavy jobs, a corded grinder is the better choice. If you value mobility and flexibility, a cordless grinder may suit you best. For professional use, many workers keep both so they are ready for different situations.

Choosing between corded and cordless depends on how and where you plan to use your grinder.

Price and Budget Considerations

When choosing an angle grinder, budget is often a big factor. Prices vary based on size, power, and features, so it helps to know what to expect.

Price Ranges

- Entry-level models: Basic 4-inch or 5-inch grinders for light use often cost between $40 and $100. These are suitable for DIY users or occasional projects.

- Mid-range models: More powerful 5-inch to 7-inch grinders with higher RPM and wattage usually cost between $100 and $250. They offer better durability and are suitable for regular use.

- Professional models: Heavy-duty grinders with high power (up to 2,000 watts or more), brushless motors, and safety features can range from $250 to $500 or higher. These are designed for daily, long-term use in construction or metalworking.

ROI Analysis: Professional vs Amateur

For professionals, investing in a high-quality grinder often pays off. A tool that cuts faster, lasts longer, and needs fewer replacements can save time and money in the long run. For example, a $300 grinder that lasts several years with heavy use is a better value than replacing cheaper grinders every few months.

For DIY or amateur users, it may not make sense to buy the most expensive model. If you only use a grinder a few times a year, an entry-level or mid-range option provides enough power without straining your budget.

Balancing Price and Value

Think about how often you will use the tool, what materials you plan to cut, and how much reliability matters to you. Spending a little more on the right grinder can prevent accidents, reduce frustration, and improve results. Choosing the best grinder for your budget means finding the right balance between price, performance, and long-term value.

Choosing the Right Angle Grinder for Concrete Cutting

Cutting concrete is one of the toughest jobs for an angle grinder. Not all grinders can handle it, so choosing the right one is very important.

Power and Torque

Concrete is harder than metal, so you need an angle grinder with high power and torque. A 7-inch or larger grinder is usually best. Smaller grinders can cut concrete, but they take more time and wear out discs faster.

Discs for Concrete

The most effective choice is a diamond blade. These blades have a strong edge that can cut through concrete, bricks, and stone. A concrete grinder disc is also useful for smoothing rough concrete surfaces after cutting. Always check that your disc is the right size for your grinder.

Tips for Safe Concrete Cutting

- Use Water if Possible: Spraying water while cutting helps reduce dust and cools the blade.

- Control the Cutting Depth: Do not force the grinder too deep at once. Make shallow passes for better control and less strain on the tool.

- Match Disc to Grinder: Never use a disc that is larger than the grinder. This is dangerous and can cause accidents.

- Wear Safety Gear: Concrete cutting produces dust and sparks, so always wear goggles, a mask, and gloves.

Use Cases

Angle grinders are great for cutting bricks, trimming concrete blocks, or shaping stone for masonry work. For larger construction projects, a bigger grinder will save time and effort.

Choosing the right grinder and disc ensures clean cuts, longer tool life, and safer working conditions.

Safety Tips When Using an Angle Grinder

Angle grinders are powerful tools, but they can also be dangerous if not handled correctly. Following safety rules protects you from injuries and helps your grinder last longer.

Wear the Right Protective Gear

Always wear safety goggles to protect your eyes from sparks and flying debris. A dust mask keeps you safe from fine particles, especially when cutting concrete. Gloves, ear protection, and sturdy clothing are also important.

Handle the Grinder Properly

Hold the grinder firmly with both hands. Keep a balanced stance so the tool does not pull you off position. Never remove the safety guard, as it shields you from sparks and broken disc fragments.

Install the Disc Correctly

Before using the grinder, make sure the disc is fitted tightly on the spindle. A loose disc can wobble and break during use. Always check that you are using the correct disc size for your grinder.

Check and Store Discs Safely

Inspect discs for cracks or wear before each use. Damaged discs should never be used because they can break apart at high speeds. Store your discs in a dry place to prevent damage.

Avoid Common Mistakes

Do not push too hard on the grinder. Let the speed of the disc do the work. Forcing the tool increases the chance of kickback and shortens the life of the disc.

By following these safety tips, you can use your angle grinder with confidence and reduce the risk of accidents.

Angle Grinder Maintenance Tips

Regular maintenance of angle grinder can extend its life and improve its performance.

Keep It Clean

After each use, clean off dust and debris from the grinder. Pay special attention to the vents because clogged vents can cause the motor to overheat. Use a soft brush or compressed air to clear them.

Check and Replace Discs

Inspect your discs and blades before and after use. Worn-out or damaged discs should be replaced right away. Using bad discs increases the chance of accidents and slows down your work. Always use discs that match the grinder size.

Lubricate Moving Parts

Some angle grinders need their moving parts lubricated from time to time. Check your user manual to see if your model requires this. Proper lubrication helps the grinder run smoothly and prevents wear.

Inspect Electrical Parts

If you are using a corded grinder, look for cracks or damage in the cord. For cordless grinders, make sure the battery is charged and stored correctly. Damaged cords or batteries should be replaced immediately.

Store the Grinder Properly

When not in use, keep the grinder in a dry place away from dust and moisture. Using a tool case is the best way to protect it from accidental damage.

With simple care and regular checks, your angle grinder will stay reliable and ready for any job.

Where to Buy: Why MaxXT Is a Trusted Power Tool Brand

Choosing the right angle grinder is only part of the process. You also need a brand that you can trust. MaxXT has built a strong reputation for making durable and reliable power tools for both professionals and DIY users.

Quality and Features

MaxXT angle grinders come with brushless EC motors, which means they run cooler, last longer, and deliver more power with less effort. They are designed with safety in mind, including strong guards, easy-to-use handles, and protective systems to prevent overheating.

Wide Range of Options

Whether you need a mini cordless grinder for light DIY work or a large industrial-grade grinder for heavy construction, MaxXT has models that fit every need. Their grinders support different disc sizes, so you can choose the right one for metal cutting, concrete shaping, or polishing.

Support for Businesses

MaxXT also understands the needs of professionals and companies. They offer:

- Bulk order options for large projects

- Dealer programs for resellers and partners

- Technical support to answer product or usage questions

- 7-day regional delivery for quick access to tools and parts

Why MaxXT Stands Out

Unlike many brands, MaxXT focuses on both performance and reliability. Their tools are built to handle tough conditions without slowing down. This makes them a trusted choice for construction workers, metal fabricators, and serious DIY users.

If you are looking for a brand that combines quality, safety, and support, MaxXT is a solid choice.If you’re also planning the rest of your workshop around your new grinder, Essential power tools for woodworking gives an overview of other key machines to consider, while How to choose the right Oscillating Multi-Tools explains how multi‑tools can complement your angle grinder for detailed cutting and remodeling tasks.

Conclusion

An angle grinder is a powerful and versatile tool for cutting, grinding, and polishing. Choosing the right one depends on your main tasks, budget, and safety needs. Small grinders are great for light jobs, while larger models handle heavy-duty work like cutting concrete and stone.

In this guide, we covered grinder types, sizes, discs, safety, and maintenance tips. We also explained how specs like speed and power affect performance.

MaxXT offers grinders built for both DIY users and professionals. With the right choice, you will have a reliable tool that makes your work easier and safer for years to come.

Frequently Asked Questions

Can I use an angle grinder to cut bricks?

Yes, you can use an angle grinder to cut bricks. You need the right blade, such as a masonry or diamond blade. Always use water to reduce dust and wear safety gear like goggles and gloves.

What is the smallest angle grinder available?

The smallest angle grinders are usually 4-inch models. These are light, easy to handle, and good for small jobs or tight spaces. They are popular for home projects and light metalwork.

What disc is best for cutting concrete?

A diamond blade or a concrete grinder disc works best for cutting concrete. These blades are designed to handle hard surfaces without wearing out too quickly. Make sure to match the blade size with your grinder size for safety.

Can I put a 7-inch disc on a 5-inch grinder?

No, you should never put a 7-inch disc on a 5-inch grinder. It is unsafe because the larger disc will not fit properly, and it could break while spinning at high speed. Always use the correct disc size recommended for your grinder.

Can I use an angle grinder for stone or tiles?

Yes, with the right disc, an angle grinder can cut and shape stone or tiles. A stone-cutting disc or diamond blade is the best choice for these materials.