Table of Contents

ToggleWhy have this tool within reach? It is one of the few good tools that you would wish to have in the workshop. Everything you would require on how to use an oscillating tool is found in this guide: choosing the right attachment for cutting, sanding, scraping, and many more.

What Is an Oscillating Multi-Tool and Its Working Principle?

An oscillating multi-tool is a handheld power tool meant to fulfill multiple capabilities in its functions. This versatility arises from its fast reciprocating motion, which sets it apart from conventional power tools. Normally, the tool alternately oscillates in small arc movements at a rate of approximately 20000 oscillations per minute.

Thus, what is the work done by such an oscillating motion? It applies fine cutting, sanding, grinding, scraping, and polishing without tearing through materials or harming adjacent surfaces, thanks to that very special motion.

Some Important Things About an Oscillating Multi-Tool:

- Interchangeable attachments: This is basically equipping your multi-tool to replace blades, scraping pads, and other instruments that can be replaced easily.

- Variable speed control: To change the oscillating rate of the tool for different materials and applications.

- Compact design: Best for tight spots, corners, and hard-to-reach areas.

- Corded or Cordless: Either option allows full portability and consistent power.

General Uses/What Can You Use an Oscillating Multi-Tool For?

- Cutting wood, metal, drywall, PVC pipes, and even the existing nails.

- Sanding edges of tight corners, baseboards, and furniture.

- Removing old paint, caulk, or dried glue.

- Carbide grit blades to remove grout from between tiles.

- Flush-cutting door jambs, trim, and floorboards.

An oscillating multi tool is more precise and flexible than other power tools like jigsaws and rotary grinders. A jigsaw is best for long straight cuts, and a rotary tool is best for engraving or grinding. Therefore, in contrast, an oscillating multi tool is about control, precision, and multitasking, especially in small, tight, or difficult to reach areas.

This tool is an all in one combination of five separate tools, whether to patch drywall, remodel a bathroom, or prepare a surface for painting. That is why it has become a prime choice for the pro builder or a DIY-er.

Reasons for Learning to Work with an Oscillating Multi-Tool

Learning the right operation of an oscillating multi-tool offers you cleaner results and a longer life for the tool and attachments. Here are the benefits:

- Accuracy & Control: It gives neat finishes to difficult corners, plunge cuts, and fine sanding.

- Versatility: One tool can perform many functions with the help of different attachments.

- Time Saving: An oscillating multi tool saves time and improves efficiency by drastically reducing the number of tools on a job site.

Oscillating Multi-Tool Types: Choosing the Right Oscillating Multi-Tool

When selecting the proper oscillating multi-tool for your work site, it is important to understand the power source behind it.

Corded Oscillating Multi Tool

Corded tools supply dependable and uninterrupted power, making them great for long projects such as cutting hardwood or sanding large areas. You will not have to worry about charging and simply need to plug the tool in.

Corded options do lack mobility, but there are times when you want to be stationary. This is ideal for the garage, workshop, or job site tasks that you will be doing regularly and rely on steady power.

Cordless Oscillating Multi-Tool

Cordless options have lithium-ion batteries. The tool will give you great flexibility without sacrificing too much power. Cordless options are good for use in the field or in difficult zones to reach and work.

The only consideration is with battery life if you are working all day. For the professionals who are using mobility as part of their trade and may be required to travel to remote or different locations, battery life will be ideal.

Brushless Oscillating Multi-Tool

Brushless oscillating multi-tools, like the models from Maxxt-Tech, allow for better torque, longer use on one charge, and less maintenance.

They run cooler and quieter and are made for seeing tough environments, which makes them great for serious contractors and people who buy a lot of them. It is for seekers of tools that last and work like professionals.

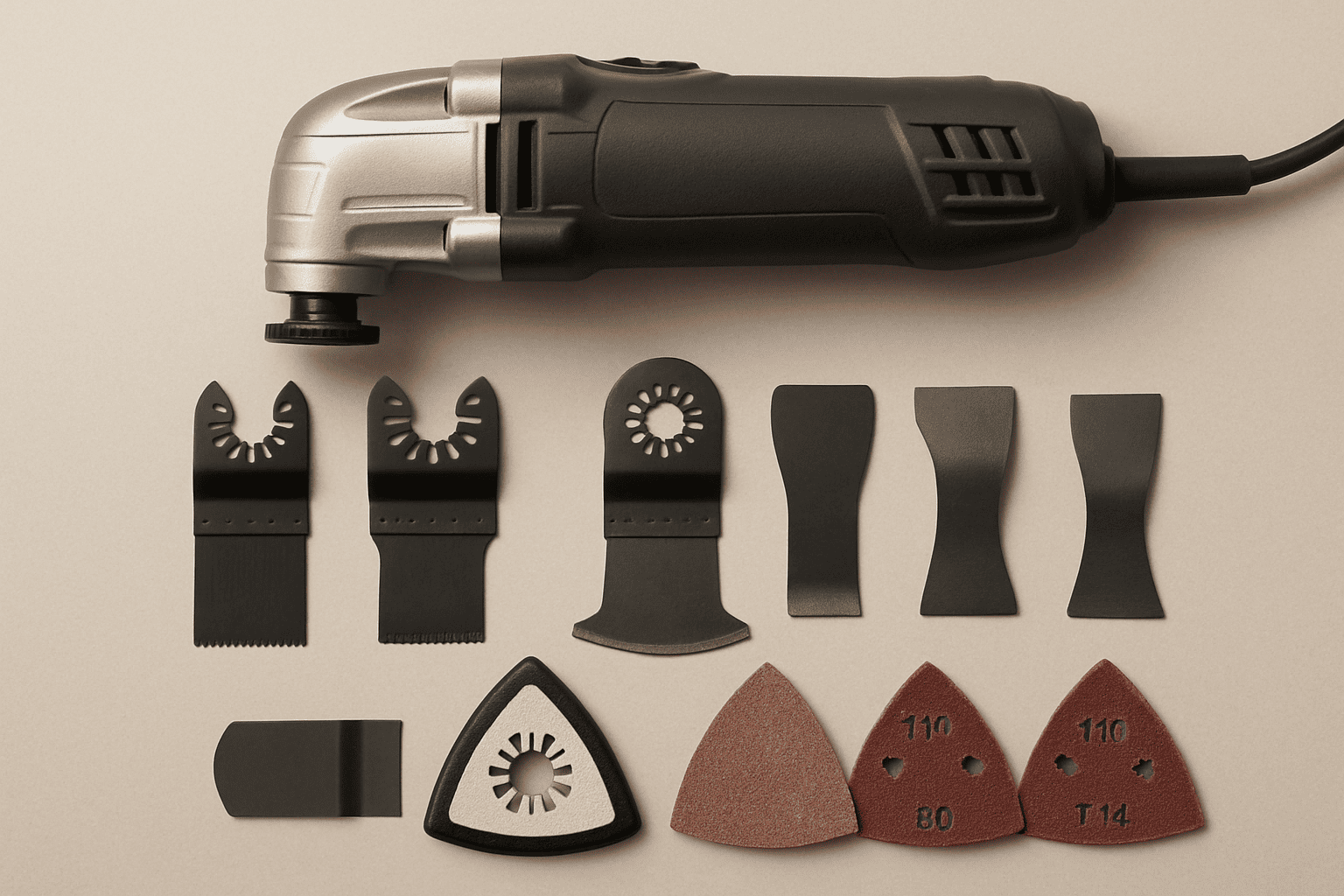

Essential Oscillating Multi-Tool Attachments & Blades

It isn’t just the tool that makes the oscillating multi-tool essential; it’s the attachments. It can cut, sand, scrape, and polish accurately with the correct accessory. The following are the correct attachments for the correct materials.

1. Cutting Blades for Wood, Metal, Drywall, etc.

Cutting attachments are the most important tools in the oscillating universe. The right blade will give you a nice, clean cut every time. So if you are installing flooring, trimming casing, cutting metal pipe, etc, always use the correct blade so the pieces do not splinter or burn.

Types of cutting blades:

- Wood Blades: Wide blades with straight teeth make good plunge cuts and quick trimmers. Perfect for notching, door jams, and baseboards.

- Metal Blades: Suitable for Bi-metal blades to cut through nails, screws and thin steel. Choose more robust teeth to cut through tougher alloys.

- Drywall blades: They typically either have fine teeth or semi-circular designs. They make clean, dust free cuts, so they’re perfect for when you’re installing electrical boxes or ventilation ducts.

For multi material jobs (say, cutting drywall that has embedded nails), your best option is a bi-metal or carbide tipped blade.

2. Scraping Blades, For Adhesives, Paint, and Sealants

Scraping blades are your best choice for removing old caulk, dried glue, stubborn flooring, or tile adhesive. They turn a long, boring job into an efficient, organized job.

Types of scraping blades

- Rigid Scraping Blades: It is solid and inflexible, but is great for dense or hardened material, like mortar, dried adhesive, or thick grout.

- Flexible scraping blades: When removing soft material, such as silicone sealants, paint buildup, or even window film, they are more forgiving.

They remove the buildup quickly without damaging the surfaces below.

3. Sanding Pads: For Detail Work in Small Areas

Best for corners, trim, and areas where it is difficult to get a tool in.

Pros:

- A hook-and-loop backing to easily swap out pads.

- Comes in a range of grits: coarse grit (paint stripping), medium grit (smoothing), and fine grit (wood finish).

- Does not swirl when using light pressure and leaves a smooth, even finish.

You get a smooth, even finish as long as you are using the right speed setting and light pressure to avoid thickness. Using heavy pressure can cause swirl marks and burns on the surface that you are finishing.

How to choose the right oscillating multi-tool blades?

Pick quality over quantity to get better, cleaner results and increase time using your tools.

Look for:

- Universal Fitment: Can use one brand of blade on another brand of tool.

- Coated Edges: Titanium or carbide coatings for durability.

- Blade Geometry: Plunge, segmented tips (or punctuated tips) for specific tasks.

As always, make sure to match the blade to the toughest material in your project. You should also avoid cheap knockoffs as they will wear faster and are not as efficient.

How to Use an Oscillating Multi-Tool: A Step-by-Step Guide

The most vital step to getting better at the oscillating multi-tool is the process of learning to use it. After an experience of using it for a bit, you will find that you will have the ease of making nice cuts, have a smooth finish and produce quick results by spending the least amount of money on blades, and have no regrets about damaging your materials. You might not end up being perfect, but I am sure you will be pleased with the improvements to your work.

This is a complete step-by-step instruction manual to help you maximise your tool usage, whether you are using it to cut drywall, sand a cabinet, or scrape caulk off.

Step 1. Health and Safety Before You Use Your Multi-Tool

Before you start up, your first step has to be safety first. Oscillating tools might be small, but that does not mean that they are not dangerous, especially at high speeds.

Personal Protective Equipment (PPE)

- Gloves: You need to wear gloves to protect your hands from debris and include a layer of protection against vibration fatigue.

- Goggles: Safety goggles will prevent sawdust, metal filings, and wood chip debris from getting into your eyes.

- Dust mask or respirator: This is most important when sanding paint, cutting drywall, or using glue.

Your Work Environment

- Always use clamps or a vice to hold the workpiece safely. A board or tile that is moving while you are cutting or sanding could ruin your cut and possibly cause you harm.

- Remember to unplug it or remove the battery before changing blades or attachments

Step 2: Installing Blade & Attachment

Most oscillating tools have a blade change system that requires no tools.

Here’s how to do it:

- Lift off the clamp or lever to release the mechanism.

- Position the blade and align it with the mount. Many blades can be assembled at different angles (0°, 45°, 90°).

- Tighten the clamp or lock. A loose blade can vibrate, slip, or run poorly.

- Be sure to check alignment before turning on the saw.

Step 3: Speed & Oscillation Setting

Being able to control speed is important. Not having the right speed setting can prevent burning the blade, splintering the wood, and ensuring the sanding will be smooth.

When should someone use a slow speed?

- The material is delicate (plastic/veneer).

- The sanding or polishing must be precise.

- You need to minimize heat buildup during continuous cuts.

When to go faster:

- Harder materials (metal, hardwood, grout).

- Making fast cuts or plunging straight down.

- Aggressor scrapers/sanding.

The tools we are trained on easily have slow to fast variable speed dials or trigger-based speed. It just comes down to the feel and resistance.

Step 4: Cutting Techniques

Clean cutting is important, whether you are doing home improvement or professionally.

Straight Cuts (Wood, Metal, Drywall):

- Mark your line with a pencil or chalk.

- Start at the edge of the blade, press lightly down, and let the oscillation do the cutting.

- Do not force the tool; let it vibrate through the material for better results.

Cutting a Nut or Bolt:

- Use a bi metal blade, especially made for cutting metal (known as a metal cutting blade).

- Make sure to tightly clamp the nut.

- Cut slowly and steadily so you do not accidentally slip into something else nearby.

How to make a plunge cut/making a plunge cut:

- Using a blade that is straight and narrow, start at an angle and slowly rock the blade into the material.

- Once there, level the blade and move forward slowly.

- Great for drywall, floors, and making exact holes.

Step 5: Sanding and Finishing

To transition from cutting to sanding, you only have to change the attachment.

How to Sand Effectively:

- Attach a triangular sanding pad with hook-and-loop sandpaper.

- Choose the proper grit: for removal, coarse (60-80); for smoothing, medium (120-150); for finishing, fine (220+).

- Apply light, even pressure.

- Use overlapping strokes, especially on corners and mouldings, and furniture edges.

Step 6: Cleaning & Storage

You have to do routine maintenance, that’s what keeps your tool performing like new.

- Remove dust with a dry brush or boom box compressor.

- Wipe the housing and attachments with a soft cloth. Apply a light oil to the moving parts if not used regularly, and make sure you oil the blade clamp or pivot/wear points.

- Store in a dry place, out of moisture and away from direct sunlight.

- Use the case it comes with, or keep it elevated off the ground

Tips and Tricks for Advanced Users

After mastering cutting, sanding, and scraping, these advanced tips will help you work smart and have cleaner and quicker results.

Being precise in awkward and difficult places, equipped to be more efficient when working in small or difficult spaces:

Oscillating tools are perfect for small or odd spaces:

- Use offset blades to get into corners of baseboards and such.

- Use a narrow or semi-circle attachment to do the small detailing or work on the inside of something.

- Locking the blades’ angle to lock in at 0°, 45°, or 90° helps.

- Use painters’ tape to mark the depth of the cut, which helps prevent overcutting.

- Work slowly when the project requires precision.

Avoid discounts and conflicts in the life of a project.

Best Techniques for Grout Removal and Tile Cutting

Oscillating power tools outperform chisels for grout and tile work. Going through the methods:

Grout Removal:

- Use carbide or diamond grit blades.

- Hold the tool at an angle and guide it. Work gently.

- Short passes will help avoid cracking tile while being efficient.

- Clear the dust frequently to see.

Tile Trimming or Cutting:

- If scoring/light cuts, use a semi-circle diamond blade.

- Dust will fly, always use a mask and goggles.

- If making plunge cuts, use a grease pencil to mark cuts and score they be deeper.

- Moving slowly helps avoid chipping or overheating.

Once these techniques were used, it was easy to get clean and precise tile sets, very good for renovation and repair jobs.

Maxxt-Tech’s B2B Solutions and Related Products

Reliability is not only important for contractors and workshop managers it is also a must for procurement groups. Maxxt-Tech understands what professional job sites require does offers business-to-business solutions that are designed to accommodate their needs and provide performance, scalability, and value for years to come. Ready to level up your toolkit? Contact Maxxt-Tech today.

Questions and Answers

What’s the difference between an oscillating tool and a multi tool?

They are the same tool. The term “multi-tool” came from the fact that it can do many things with different attachments.

Can you cut a straight line with an oscillating tool?

Yes. Use a straight edge guide and a plunge blade.

Will an oscillating tool cut skin?

Yes, it will hurt you, just like any power tool. Always use the correct protective gear and safety procedures.

Conclusion

An oscillating multi-tool that you use frequently does not merely make your tasks easier; it changes the way you cut, sand, scrape, and finesse in lots of materials. An oscillating multi-tool can accomplish so many different tasks, with the right attachments, whether you need to make plunge cuts in drywall or do tricky sanding on trim.

It becomes more than a tool once you’ve established that you can use it constantly and correctly. It becomes your day-to-day solution. That is especially the case when you’re using a brushless oscillating multi-tool that is designed for performance and power. Whether you are solo or leading a team, having the right tool in your hand is game-changing.