Table of Contents

ToggleImpact wrenches are a very diverse and special kind of tool that delivers high torque to tighten or loosen bolts and nuts efficiently. Pneumatic wrenches, a type of impact wrench that is powered by compressed air, are widely used in professional workshops, automotive repair shops, and industrial environments. Going with the right tool totally depends on your workspace, mobility needs, torque requirements, and the types of projects you deal with regularly.

Electric impact wrenches offer maximum portability, quick setup, and flexibility, making them ideal for mobile mechanics and DIY enthusiasts. Pneumatic wrenches provide high-end torque, continuous performance, and are made for heavy-duty tasks. Essentially, electric wrenches focus more on convenience and mobility, while the pneumatic versions prioritize raw power and durability for long hours of use.

What Is an Impact Wrench?

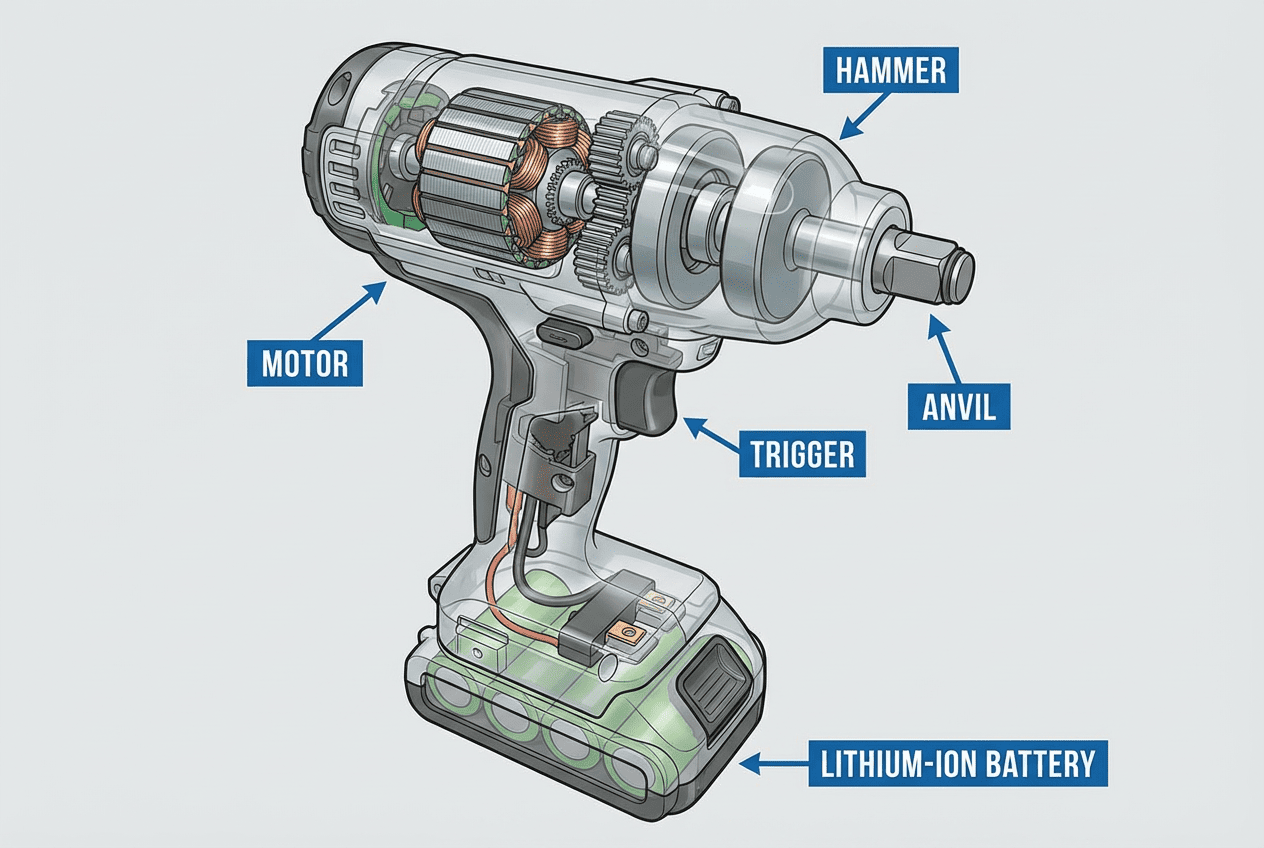

An impact wrench is a power tool that fosters rotational force with a hammering mechanism in order to tighten or loosen fasteners much quicker than manual tools. Its signature “impact mechanism” works by a hammer inside the tool repeatedly striking an anvil, which then converts energy into sudden bursts of torque. This hammer-and-anvil system allows users to handle more stubborn stubborn bolts, bolts, and nuts with ease, making the tool indispensable in automotive and industrial applications.

There are two primary types of impact wrenches: electric and pneumatic.

Electric wrenches

Electric wrenches are powered either by mains electricity or rechargeable batteries, offering mobility and ease of use.

Pneumatic wrenches

Pneumatic wrenches rely on compressed air, providing extremely high torque, a lightweight design, and the ability to operate continuously without overheating.

Common uses include:

- Automotive repair

- Industrial assembly lines

- DIY enthusiasts need a reliable tool for furniture assembly, small repairs, or mechanical projects.

How Does an Electric Impact Wrench Work?

Electric impact wrenches function using a motor-driven mechanism; the motor drives a hammer-and-anvil system to produce a charge of rotational force, effectively loosening or tightening fasteners. Electric models are either completely corded, using mains electricity for continuous power, or cordless, powered by rechargeable batteries for maximum portability.

Corded electric

Corded electric wrenches deliver consistent performance and are ideal for workshops with reliable access to electrical outlets.

Cordless wrenches

Cordless wrenches are highly portable, making them perfect for roadside repairs, outdoor projects, or mobile workshops where flexibility is crucial.

What these are known for is their portability, ease of setup, and subtle operation as compared to the pneumatic models. They don’t need a compressor or an extensive setup, making them highly convenient for small spaces or one-off tasks.

Looking at their flipside, battery-powered units have a specific runtime, and with heavy batteries, it can make the tools even more difficult to operate. Replacement batteries and parts may also be more expensive than maintaining a pneumatic system.

Their core functionality for electric impact wrenches is diverse:

- They all work well for quick automotive tasks, like changing tires or performing small mechanical repairs.

- Professionals who travel to various job sites prefer cordless electric impact tools and wrenches because they combine adequate torque with portability.

How Does a Pneumatic (Air) Impact Wrench Work?

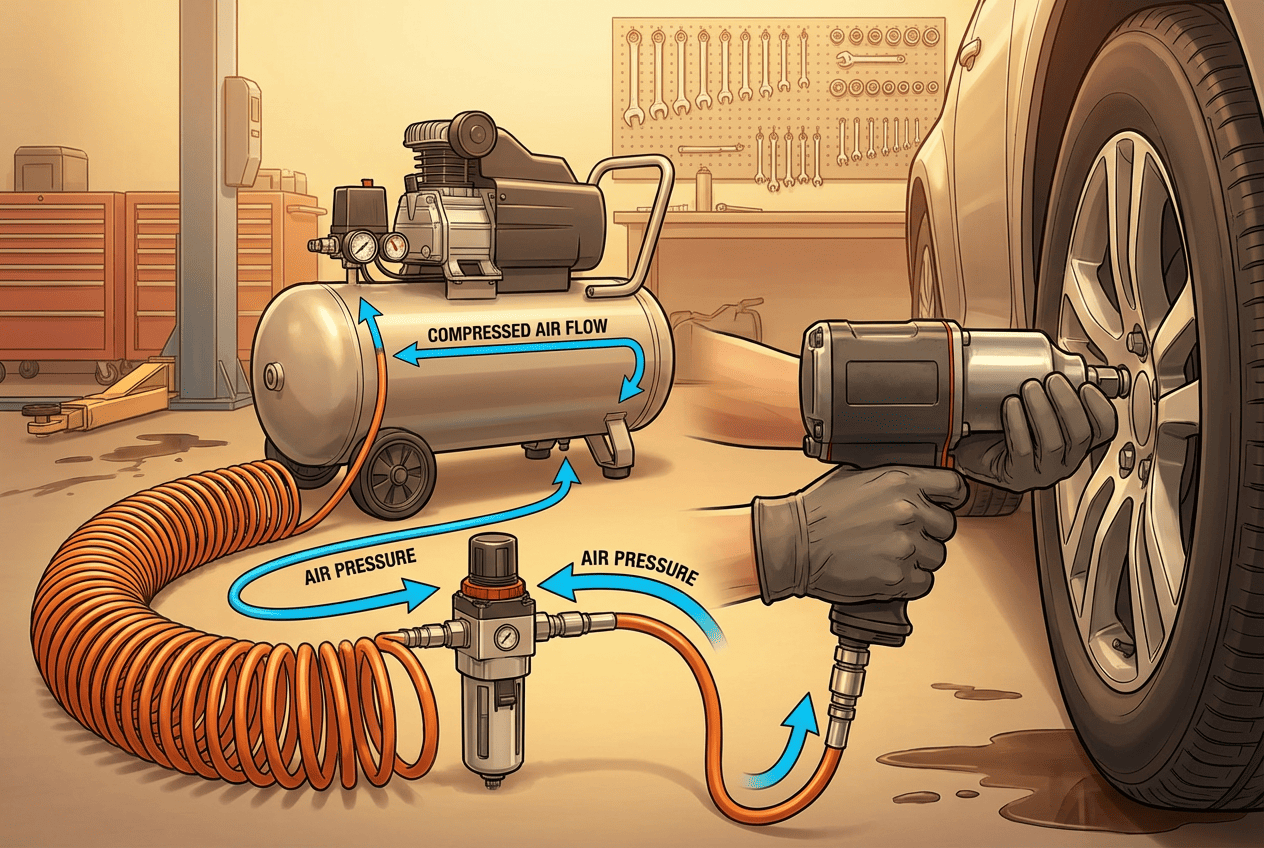

Pneumatic impact wrenches completely depend on compressed air to generate more torque. A compressor pumps air through a hose into the wrench, spinning the internal hammer-and-anvil system for delivering powerful bursts of force. The tool itself stays lightweight because the energy comes from the compressor rather than an internal motor.

A usual pneumatic setup comprises a compressor, an air hose, and a regulator to control airflow. This setup allows pneumatic wrenches to deliver an extreme end torque, making them optimal for tasks that require continuous use, such as working on trucks, industrial machinery, or even professional auto repair.

Pneumatic wrenches work very well for applications that involve challenging fasteners or bolts that cannot be loosened with an electric wrench. In general, they are lighter in the hand than electric units; however, limited mobility is reduced since the wrench must be connected to a hose, and the compressor must be nearby. In addition, upkeep of the pneumatic system requires checks of the hoses and fittings, draining of the compressor tank of moisture, and lubrication of in-line moving parts to ensure reliable long-term use.

Electric vs Pneumatic Impact Wrench – Key Differences

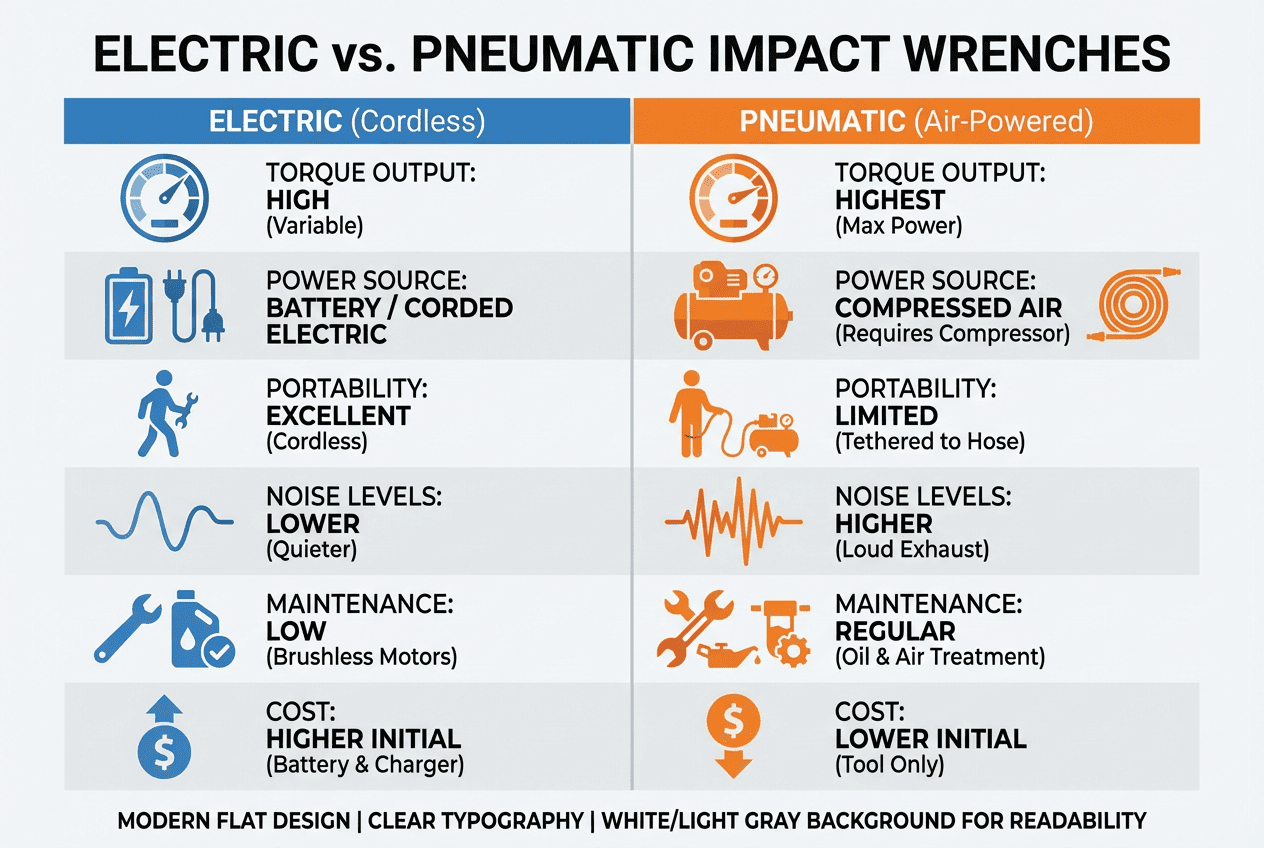

The differences between electric and pneumatic impact wrenches mainly come down to power source, torque output, portability, maintenance, and overall cost. Here’s a clearer breakdown:

1. Torque Output

- Electric: Typically 300–900 ft-lbs

- Pneumatic: 400–1,200+ ft-lbs, depending on air pressure and CFM Pneumatic models deliver more sustained torque for demanding tasks.

2. Power Source

- Electric: Runs on electricity (corded) or batteries (cordless).

- Pneumatic: Requires compressed air at 90–120 PSI, with the compressor supplying airflow.

3. Portability

- Electric: Extremely portable, ideal for roadside and mobile repairs.

- Pneumatic: Limited mobility due to the air hose and compressor requirement.

4. Noise Levels

- Electric: Quieter operation, suitable for home garages.

- Pneumatic: Louder and more suited for industrial settings.

5. Maintenance

- Electric: Low maintenance; mainly battery care.

- Pneumatic: Requires checking hoses, fittings, lubrication, and draining moisture from the compressor.

6. Cost

- Electric: Higher initial tool cost but no compressor needed.

- Pneumatic: Tool is cheaper, but total cost rises with compressor investment.

Choosing Between Electric and Pneumatic – A Buyer’s Decision Guide

When selecting an impact wrench, it’s important to consider your particular needs. If you already have a compressor and operate primarily in one location, a pneumatic wrench is a strong choice for extreme torque and continuous applications. Suppose the mobility is crucial, like having roadside repairs, home projects, or mobile workshops, an electric wrench offers flexibility without ever needing heavy equipment. Also influencing elements are budget and utilization frequency. While pneumatic wrenches do well in professional workshops or industrial settings where continuous, high-torque output is required, electric wrenches are ideal for sporadic chores, fast fixes, and tiny projects.

Glossary & FAQs

Glossary

- PSI: Pounds per square inch, measuring air pressure in pneumatic tools

- CFM: Cubic feet per minute, indicating airflow supplied to the wrench

- Torque: Rotational force applied to fasteners

- Drive Size: Diameter of the square drive on the impact wrench

- Hammer Mechanism: Internal system delivering bursts of torque

FAQs

Is an electric impact wrench powerful enough for lug nuts?

Yes, most modern electric impact wrenches can remove and tighten standard lug nuts on cars, SUVs, and light trucks. For larger trucks or industrial vehicles, a pneumatic model may be more effective.

What compressor size do I need?

A compressor delivering 90–120 PSI and 4–6 CFM is typically sufficient for pneumatic impact wrenches used in automotive and workshop settings.

Can I use both types in one workshop?

Yes. Many professional workshops combine electric wrenches for mobile or occasional tasks and pneumatic wrenches for high-torque, repetitive jobs.

How long do impact wrench batteries last?

Battery life depends on voltage, capacity, and usage. Lithium-ion batteries generally provide 30–60 minutes of continuous operation, with recharge times ranging from 30 minutes to two hours.

About Maxxt-Tech: Professional Impact Wrench Solutions

Maxxt-Tech presents a comprehensive selection of impact wrenches that utilize electric, pneumatic, and cordless power sources. Due to their fabrications and design, their impact wrenches and accessories are both able to be a dependable option for the serious semi-professionals to those who work in various fields with limited impact wrench use.

Maxxt-Tech also has everything you need for a proposal for B2B and OEM. A custom line of impact wrenches is available for businesses that are looking for an option that provides trustworthy and performance-based reliability. The precision designs and full-factory design process create a product that has provided Maxxt-Tech as a trusted name for professional push-button technology.

Final Summary and Recommendation

The choice between electric and pneumatic impact wrenches all comes down to your mobility, power, and usage. Electric impact wrenches are highly optimal for portable applications, quick and instant setups, while the pneumatic models excel in workshops or industrial environments requiring sustained high-end torque output.