Table des matières

BasculerAirless paint sprayers are professional-grade tools that meet the evolving demands of consumers and industries for high-quality finishes.These tools deliver a smooth, uniform finish in less time, which has driven strong adoption across construction, automotive, and industrial sectors.

Airless paint sprayers have developed in tandem with advancements in paint technologies, such as water-based and UV-curable paints, so they are perfect tools for the application of new formulations.

There are three main airless spray gun types: pneumatic, electric, and gas-powered. This blog focuses on airless paint sprayers.

Understanding Airless Paint Sprayers

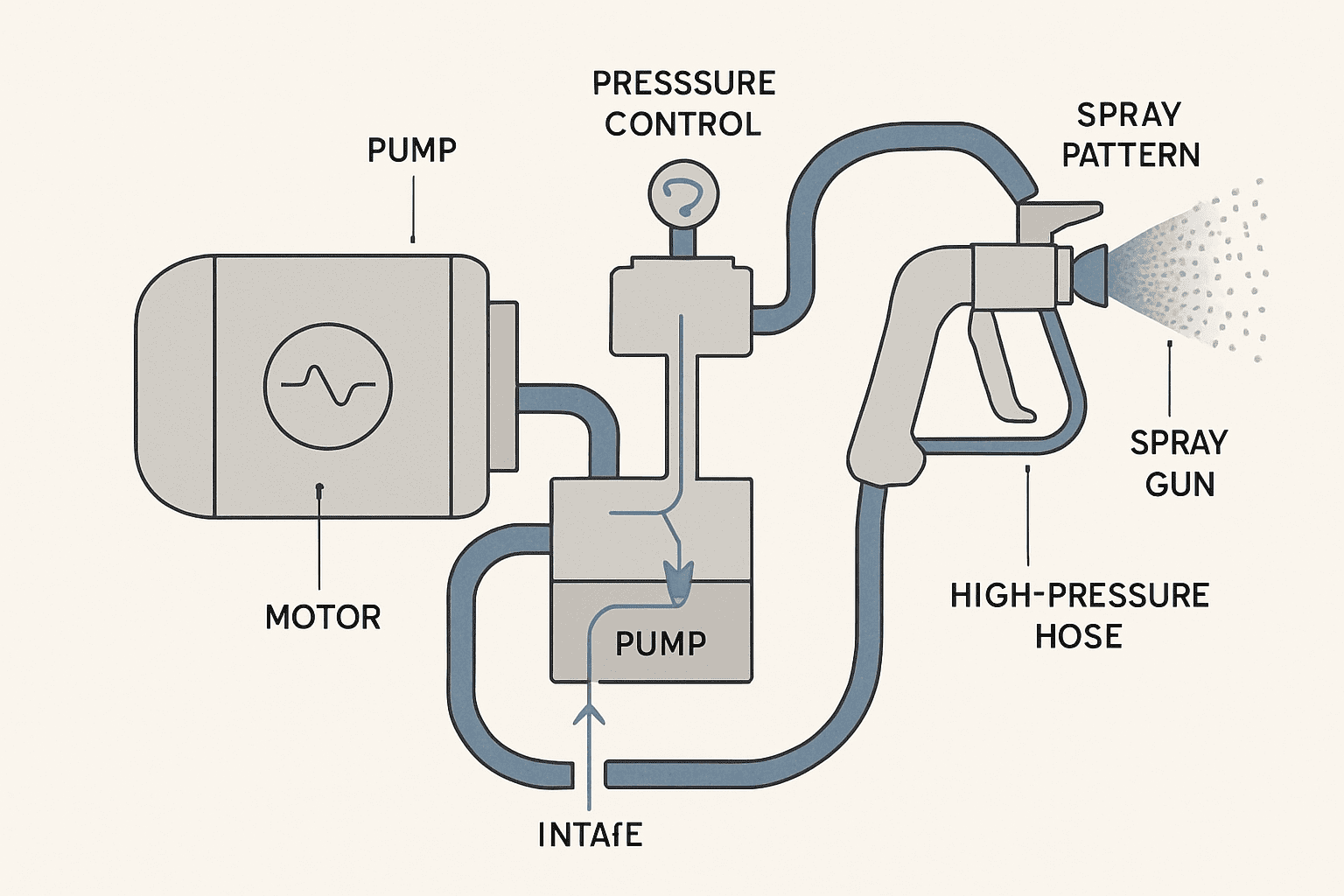

Airless paint sprayers work with high pressure. A pump is used to pressurize the paint up to approximately 3000 psi (pounds per square inch of pressure), which forces paint through a specialized hose into a small opening in the sprayer nozzle, breaking it into a fine spray:

The spray tip or nozzle is at the end of the sprayer and determines the spray pattern. Atomized paint produces an even coat that can spread quickly over large surfaces, making it an efficient choice for professional and industrial applications.

Airless Paint Sprayers at a Glance

| Taper | Power Source | Best For | Advantages | Limitations |

| Electric Airless Sprayers | Standard electricity (motor + piston pump) | Large residential & light commercial projects | Smooth, professional finish; covers large areas quickly | Dependent on power source; cord length limits mobility |

| Hydraulic Airless Sprayers | Hydraulic pump (piston/diaphragm) | Heavy-duty industrial, bridges, commercial buildings | Extremely high pressure (>3,000 psi); handles thick coatings | Risk overspray, paint waste, exposure to fumes |

| Direct Drive Gas-Powered Sprayers | Gas engine + piston pump | Outdoor projects (fences, barns, decks, roofing) | Portable; independent of electricity | Not ideal for nonstop, heavy-duty spraying |

| Gas-Hydraulic Sprayers | Gas engine + hydraulic pump | Industrial-scale projects (ships, warehouses, steel structures) | High mobility; continuous spraying of thick coatings | Heavy; overkill for small/medium jobs |

| Handheld Sprayers | Rechargeable batteries | Touch-ups, furniture, detail work | Compact, cordless, easy to use | Low power; can’t handle thick coatings |

| Stand Sprayers | Electricity | Medium projects (fences, basements, cabinets) | Stationary but portable with hose; lighter than carts | Limited capacity vs. cart models |

| Cart Sprayers | Electricity or gas (depending on model) | Large residential & commercial projects & multiple storeys | High capacity; mobile on wheels; powerful | Bulkier, heavier than stand/handheld sprayers |

Crucial Safety Precautions

Airless paint sprayers are dangerous equipment. They work with fluids under extremely high pressure – some reaching 5,000 psi. At this pressure, a careless movement can result in injections that are extremely difficult to treat medically and can lead to amputation.

Wearing personal protection equipment (PPE) is only the first line of defense. Equally important is how the sprayer is handled—safe operation and correct technique are critical to preventing serious accidents.

The Occupational Safety and Health Administration (OSHA) requires operators to use the following personal protective equipment (PPE).

- Protective clothing (coveralls or long sleeves) to avoid skin exposure.

- NIOSH-approved respirators.

- Chemical-resistant gloves.

- Goggles or face shields

- Hearing protection in high-noise environments.

OSHA holds employers responsible for the safe use of airless paint sprayers through training, maintaining equipment, and supplying PPE.

Step-by- Step Guide: How to Use an Airless Paint Sprayer

Pre-spraying Setup

One of the main benefits of using airless spray painters is that they can handle a wide variety of materials, so there is no need to thin paint beforehand. This tool can even handle thick paints, including heavy-bodied latex and acrylic, and oil-based paints, without requiring thinning. Instead, the operator chooses a larger spray tip designed to atomize thicker materials.

However, working in very low temperatures might require thinning of high-viscosity paints.

Setting Up an Airless Paint Sprayer

Choose the Right Tip and Filter

Selecting the appropriate nozzle size and sprayer filter is crucial. The choice will be determined by the nature of the material you will be spraying: a smaller tip size for water-based paints or stains and a larger tip size for viscous material, such as heavy latex. Choose coarse filters for more viscous materials to prevent clogging. Finer fillers are good for thinner liquids.

Pressure Relief

At all times, before operating a paint sprayer, ensure it is de-pressurized by following these steps:

- Turn off the power to the unit to stop the pump from building pressure.

- Lock the spray gun trigger to prevent accidental discharge.

- Set the sprayer to “prime mode” to redirect pressure away from the spray hose and sprayer.

- Release pressure by putting the drain tube into a waste bucket and slowly turning the pressure knob counterclockwise to release built-up pressure.

- Point the airless spray painter into a bucket, unlock the trigger, and squeeze it to release any residual pressure in the hose until the pressure gauge reads zero.

Prime the Pump

Attach the high-pressure airless paint sprayer hose securely to the pump and paint sprayer and ensure that all fittings are tight.

Place the suction tube in the paint bucket and the return tube into a waste bucket.

Switch to “prime” mode—this is a critical step that allows paint to circulate without pressurizing the nozzle. Turn on the prime mode to start paint circulating. Increase pressure slowly until fluid flows smoothly out of the drain tube with no air bubbles or water showing. Turn off the prime mode. The pump is now primed.

Prime the Hose and Paint Sprayer

At this point, the pump is full of paint, but the hose and sprayer are still full of air. To prime the entire system, you need to prime the hose and sprayer as well.

To start priming the hose and airless sprayer, turn the selector to SPRAY to pressurize the hose and sprayer.

Next, remove the spray tip, point the gun into a waste bucket, and press the trigger. Hold it down until a steady stream of paint (no air spurts) comes out.

Once the paint runs smoothly, return the spray tip.

Test the Spray Pattern

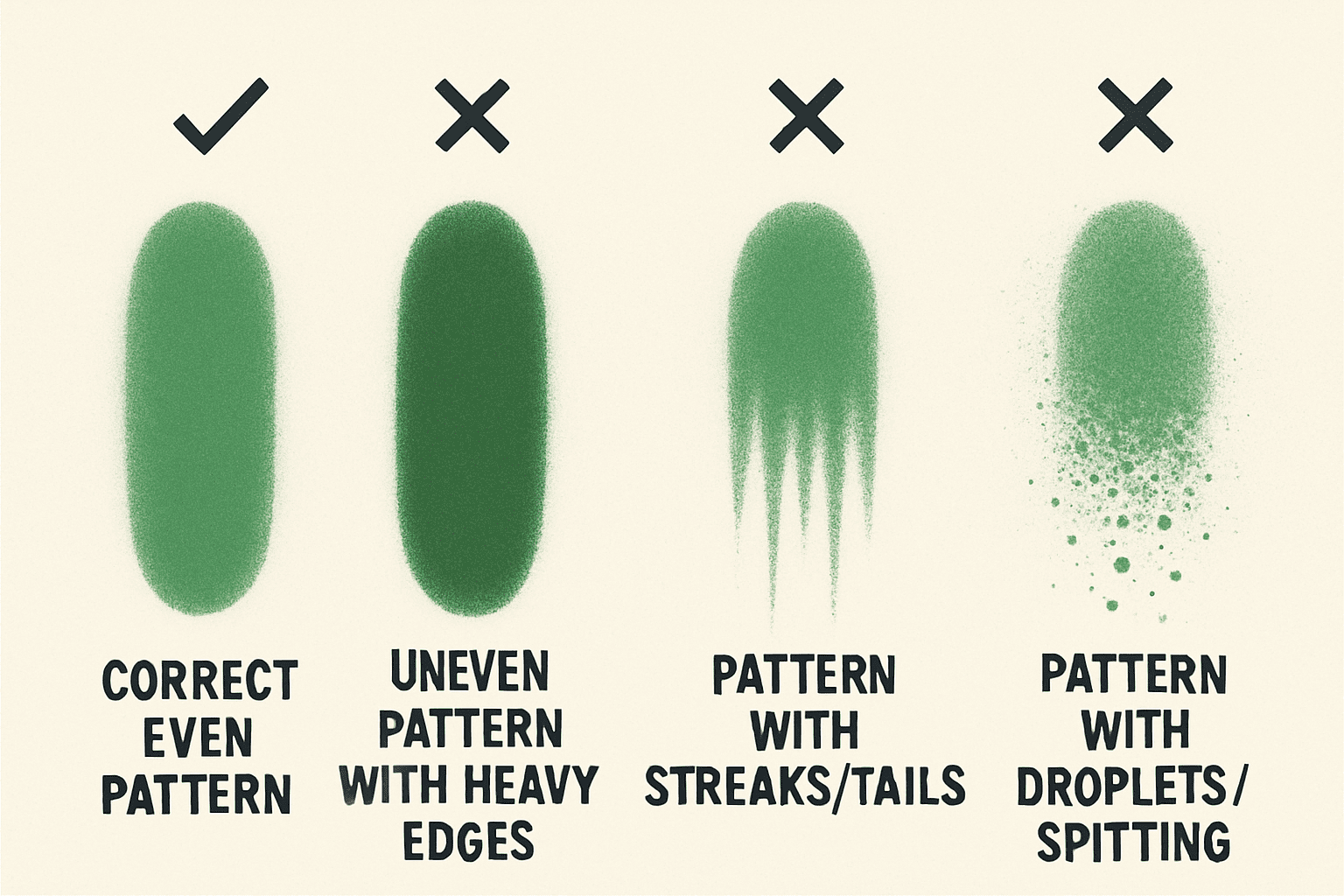

Before moving on to your actual paint job, test the spray pattern on a piece of scrap cardboard or some other material. If the spray pattern is not what you intended, you can adjust the pressure setting or choose another nozzle size to achieve a more satisfactory spray pattern.

For example, if you can clearly see thick edges in the spray pattern, it helps to increase the pressure. Increase it gradually until you no longer see thick edges and the spray pattern looks smooth with no definable edges.

Spraying Techniques

The extremely high pressure involved in airless spray painting makes it challenging to control these tools and prevent overspray. It’s a good policy to practice painting a wall with a spray gun on a piece of scrap material first if you have never used or seldom use an airless paint sprayer.

Follow these airless spray gun painting tips for spraying success.

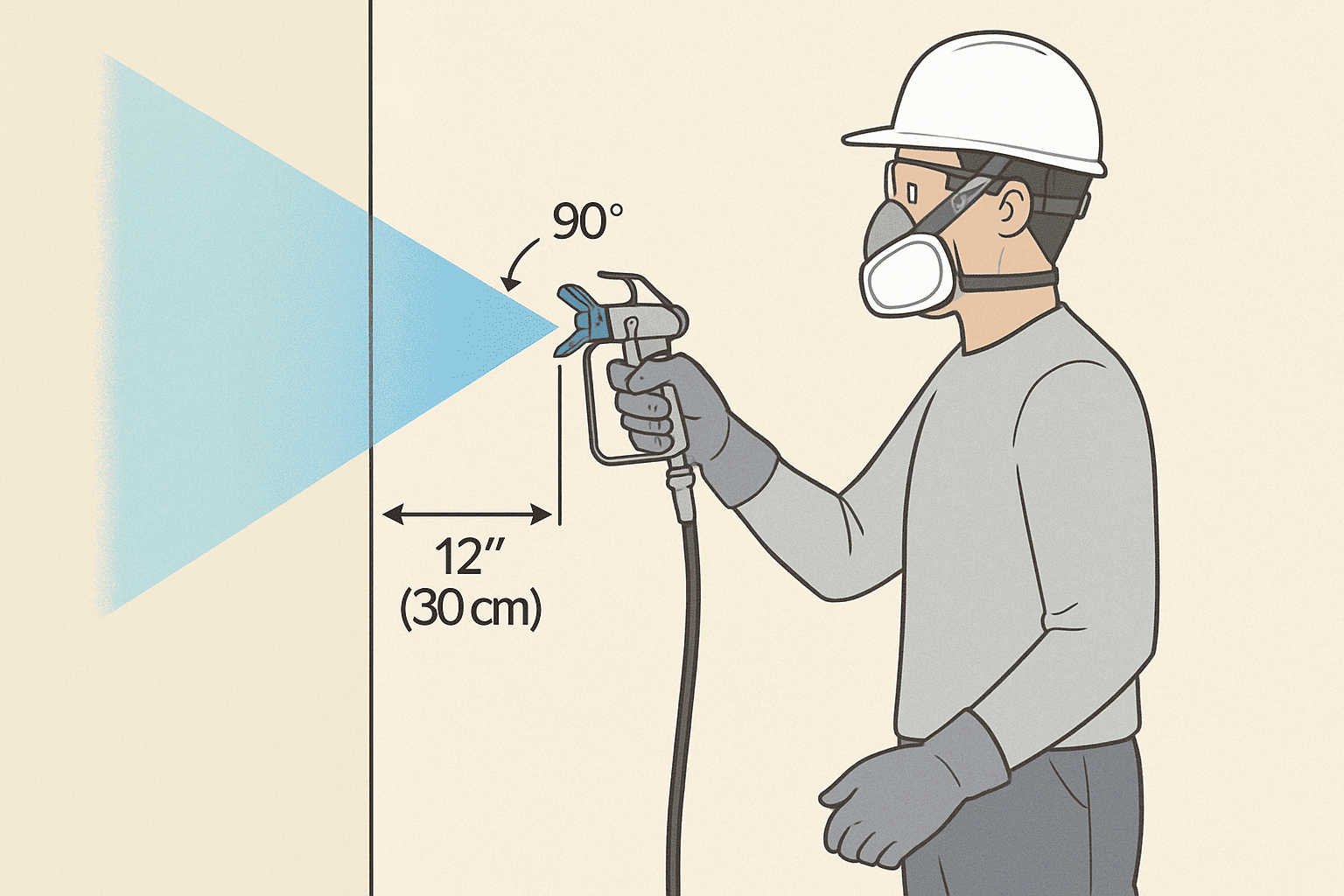

Keep Your Paint Sprayer at a Consistent Distance and Angle

Hold the sprayer about 12 inches from the surface and at a 90-degree angle. Standing too far widens the spray jet, leading to poor coverage, while holding it too close to the surface leads to heavy paint buildup and drips. Keep the sprayer aimed directly at points within your reach, never at an angle.

Trigger the Airless Paint Sprayer While You Are in Motion

Don’t trigger the sprayer while you are standing still and pointing it to the surface – this action will leave extra paint at the beginning of each stroke. Have the paint sprayer in motion at the desired distance before you pull the trigger and keep it in motion when you come to the end of the row.

Work at a Constant Speed

Keep your movements constant and move the paint sprayer at a consistent speed. Constancy throughout is necessary to achieve an even, professional-looking finish.

Spray in an Overlapping Pattern

Make sure every new line of paint overlaps the previous line by about 30 percent. This ensures an even amount of paint throughout the surface and prevents gaps. Do this by pointing the spray gun tip at the edge of the previous line.

Post-spraying Procedures

- As soon as you’re done with the painting or if your work is interrupted, disconnect the power supply and depressurize the sprayer.

- Next, take off the spray tip and guard, and clean them with warm water or solvent.

- Remove any remaining paint from the bucket and rinse it out.

- Clean the entire system by running water through it, or a solvent, depending on the paint used.

- Clean the gun filter and pump inlet filter.

- Wipe off any paint or dirt that has settled on the sprayer and its components while it was in use.

- Check for and fix leaks and loose or damaged fittings.

Don’t underestimate the time it takes to clean up after a job. Allow enough time to do it thoroughly, keeping in mind that cleaning equipment thoroughly after each use extends its longevity.

Once cleaned, store the cleaned equipment in a well-ventilated area away from moisture and heat.

Troubleshooting and Maintenance

Common Issues and Fixes

Using airless pulvérisateurs de peinture requires expertise, and encountering issues with them is not uncommon. Here are some pervasive problems that even veteran operators can experience and how to deal with them.

Uneven Spray Pattern

This is caused by worn or clogged spray tips or a clogged filter. To prevent this issue, replace spray tips when they are worn and clean the gun filter every time you use the sprayer. Ensure that you are using the appropriate tip for the paint type and surface.

An unsightly spray pattern can also result from too low pressure that can’t atomize the paint sufficiently, causing it to fall in large droplets on the surface. Investigate the pressure setting and adjust it. Test the result on a piece of scrap material until you have a smooth coating.

Overspray

Overspray is a common problem when using airless paint sprayers. Take these steps to avoid overspray:

- Fine-tune pressure settings and choose the right tip size.

- Maintain a consistent distance (about 12–14 inches) and overlap each pass by roughly 30 -50%.

- Mask thoroughly before spraying so paint doesn’t land in unintended places.

Pulsating Flow

A sudden fluctuation in paint flow can lead to an uneven finish. It can be caused by several factors, including air in the fluid line, worn or damaged pump components, clogged filters, or pressure fluctuations.

The solution may be to:

- Adjust pressure settings.

- Bleed the system to remove trapped air.

- Inspect and tighten all hoses and gun connections.

- Replace worn pump parts such as filters and piston seals.

Leaks

Paint leaking from the pump or hose connections is usually caused by loose fittings, worn seals, and damaged hoses.

This issue is easily solved by regular inspection of the equipment and replacing or fixing all damaged and worn parts immediately. Tighten all connections securely but avoid overtightening, as that can strip threads. Thread sealant can prevent leaks on fittings.

Streaks, Tails, or Large Droplets in the Paint

This is due to poor atomization when the pressure is too low to push the paint with sufficient force through the tip. Investigating both the tip and the pressure will indicate what steps you need to take to solve the issue. You may need to increase the pressure to improve atomization or use a smaller tip size.

Paint Bounces Back Off the Surface

This is also a pressure problem. When the pressure is too high, the paint can bounce off the surface and you end up with it not properly covered.

Ensure you’re using the recommended pressure for your chosen tip size and paint type. Adjust the pressure gradually until you get a clean, even fan pattern.

Maintenance Best Practices

Airless paint sprayers take a lot of punishment. Maintaining them properly is essential to keep them performing reliably over an extended time. Here is a handy checklist to refer to.

- Flush the system after each use with either water or a solvent, depending on the coating material you used.

- Clean or replace filters regularly to prevent clogging.

- After every use, check spray tips and replace them if necessary.

- Lubricate pump packings as recommended by the manufacturer.

- Regularly check hoses for cracks, leaks, or kinks.

- Clean the equipment thoroughly without fail after every use.

- Store the equipment properly in a clean, dry, and temperature-controlled environment.

FAQ

What projects are airless paint sprayers best suited to?

They are ideal for medium to large jobs such as commercial interiors, building exteriors, and infrastructure projects, where high output and professional finishes are required.

How can overspray and material waste be limited?

Study the manufacturer’s guide so you know how the equipment works, and which tip size and pressure settings to choose. Keep the spray gun 10–12 inches from the surface, and use shields or masking where needed.

What safety risks should operators be trained on?

The biggest dangers are injection injuries. Training on proper use is crucial. Other hazards include inhalation of toxic fumes and spontaneous fire hazards. PPE is critical, as is safe handling of sprayer equipment.

What are the best practices to ensure airless sprayer reliability?

Flush the entire system after each job, clean filters and tips, check hoses, and lubricate moving parts to ensure continued smooth operation.

Are airless paint sprayers cost-effective for contractors?

Yes. They do have a high upfront cost, but using them cuts labor time, boosts efficiency, and ensures professional-quality finishes, making them cost-effective if used frequently or on large projects.

Conclusion

Airless paint sprayers have earned a place as an essential tool across residential, commercial, and industrial painting projects thanks to their speed, versatility, and professional-quality finishes. Powered by electricity, gas, or hydraulic systems, they are used for small touch-up jobs, wall coverings, heavy-duty coatings and everything in between.

By selecting a top-quality sprayer, following safe handling practices, and proper maintenance protocols, operators and businesses can maximize productivity and long-term value.

MaxXT is a leading manufacturer and wholesale distributor of power tools, including cordless and airless paint sprayers. We invite our contractors, retailers, and distributors to explore our professional-grade sprayers and other MaxXT power tools for your projects and customers.

Call MaxXT today to boost your business with top-quality power tools.