Índice

AlternarNothing slows down a job like a frozen bolt. An impact wrench solves that frustration by blasting out high torque at the press of a trigger. That’s exactly what an impact wrench is designed to do. Used commonly in automotive garages, construction sites and in industrial plants, it delivers a quick burst of high torque to fasten or remove large bolts with ease.

And if you wonder what an impact wrench is, how it works, or how to use an impact wrench safely, this guide breaks everything down step by step it even guides you to professional-grade options from our impact wrench collection.

What Is an Impact Wrench and Why Is It Used?

An impact wrench is a tool that applies short, powerful bursts of rotational force to turn fasteners. Instead of straining with a breaker bar, the wrench’s internal mechanism does all the heavy lifting. This process makes it extremely invaluable anywhere high-torque fastening or loosening is needed.

Core Purpose

This tool is made to excel at removing tight bolts, lug nuts on a car wheel, or even tightening heavy machinery bolts. When you set it alongside another tool like a caulking gun, an impact wrench controls torque and delivers more efficiency. Just as professionals consider whether a caulking gun is the right choice for sealant work, DIYers often question whether an impact wrench is essential for tackling heavy bolts. With its powerful output, an impact wrench outperforms hand tools in speed and reduces operator fatigue. Explore our ferramentas automotivas for fastening and automotive applications.

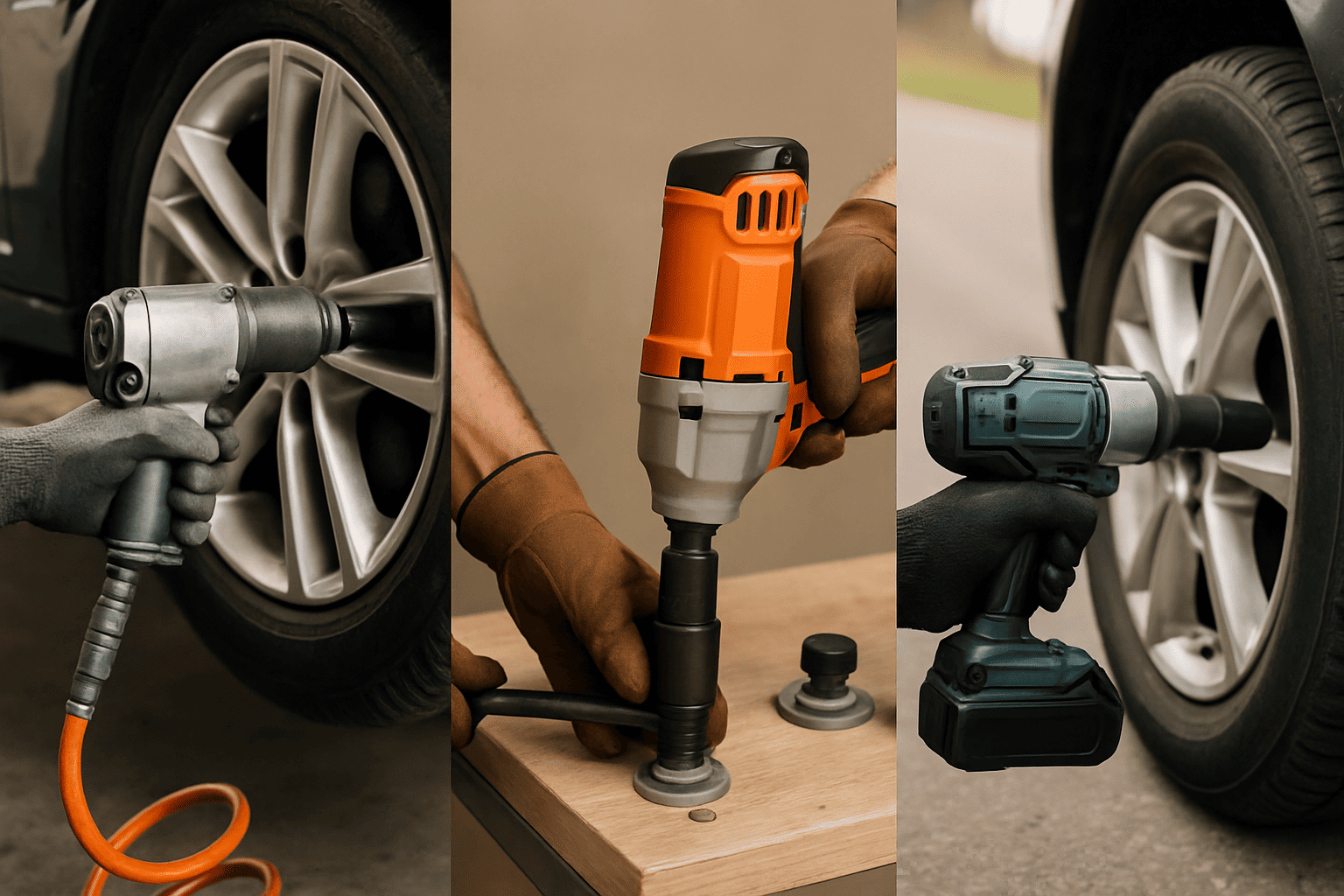

How Impact Wrench Types Differ: Pneumatic, Electric, and Cordless

Impact wrenches come in multiple formats, each of which is made for specific environments and purposes. Going with the right one depends on the job, usage, and mobility needs. Below, we are going to break down the main types, their users, and real-world applications.

| Tipo | Power Source | Best For | Typical Users |

| Pneumatic Impact Wrench | Compressed air | Highest torque, continuous shop use | Auto garages, industrial plants |

| Electric Impact Wrench (corded) | Mains power | Consistent torque without a compressor | Workshops, stationary benches |

| Battery / Cordless Impact Wrench | Rechargeable lithium-ion battery | Mobility, on-site or roadside work | Mobile mechanics, DIYers |

At a glance:

- Pneumatic impact wrenches deliver constant high torque and are the standard choice for heavy-duty jobs such as tire changes, suspension work, and machinery maintenance.

- Corded electric impact wrenches offer steady power without the need for an air compressor. They are useful for anchoring bolts, assembling scaffolding, and tightening fasteners in fixed workshop settings.

- Battery or cordless impact wrenches combine portability with strong performance. They are ideal for mobile repairs, roadside assistance, and maintenance tasks in locations where mains power is not available.

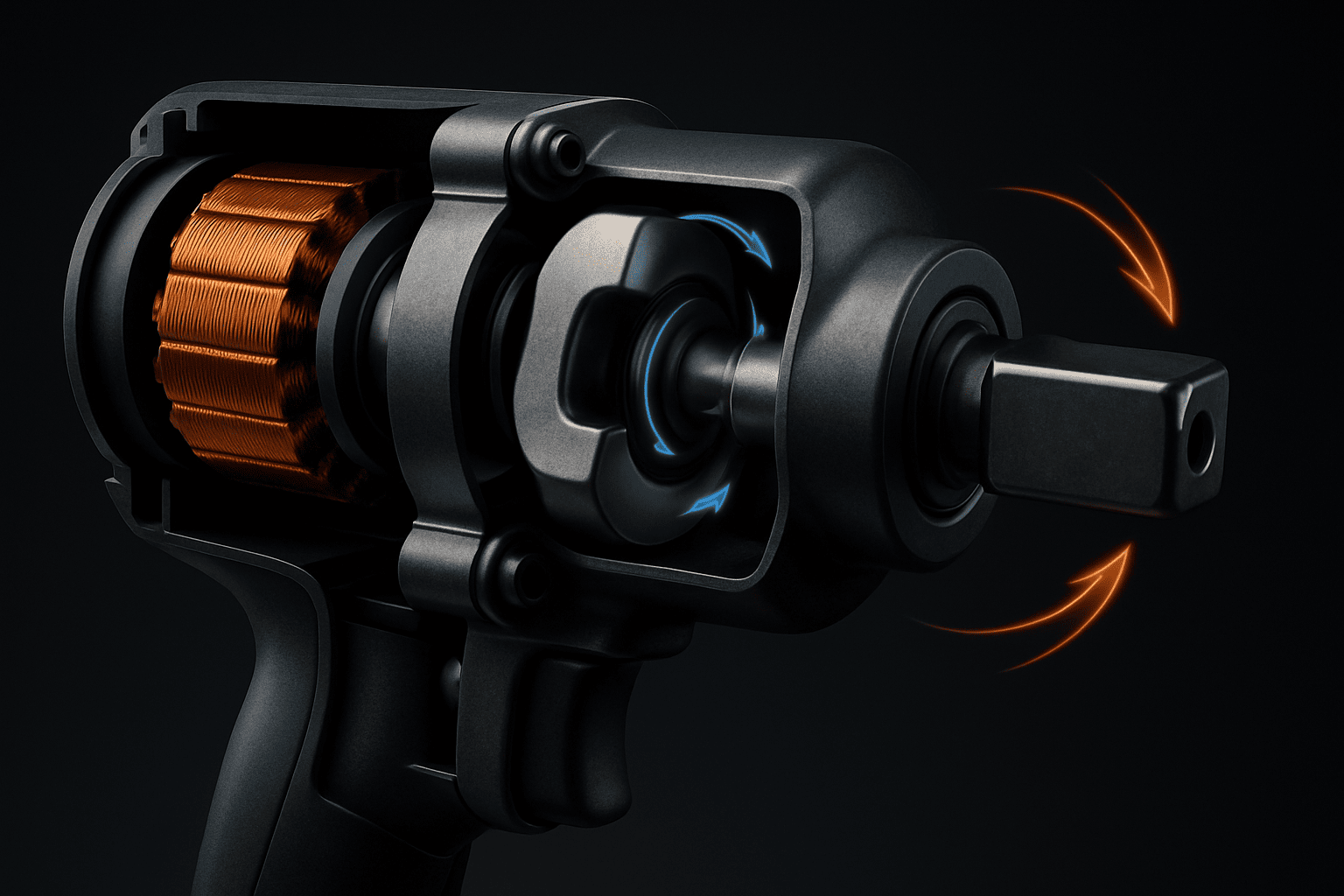

How Does an Impact Wrench Work?

An impact wrench works by delivering significant torque using a hammer-and-anvil mechanism in the housing. As the motor spins, it builds up energy in a hammer unit, which then strikes an anvil that is connected to the drive shaft. These rapid strikes produce the characteristic “impact” sound and high torque output.

Breakaway Torque vs. Fastening Torque

Two figures often listed on spec sheets are the breakaway torque (how much force the tool can apply for loosening a tight fastener) and fastening torque. High-performance or high torque impact wrenches usually advertise breakaway torque above 1,000 ft-lbs, which is ideal for rusted bolts.

How to Set Up and Prepare an Impact Wrench

Before pulling the trigger, ensure the tool is properly set up. The proper preparation protects your safety and extends the life of your impact wrench. Here’s a quick preparation guide you need to have:

- Inspect the tool. Check your impact wrench body, trigger, and drive for damage. If the impact wrench isn’t working correctly or makes unusual noises, it’s better to troubleshoot before you start using it.

- Choose proper impact sockets. Never use chrome sockets with an impact wrench; they can shatter under extreme pressure. Instead, look for sockets that are marked as impact-rated. Using the correct sockets not only protects your fasteners but also prevents accidents.

- Connect the right power source. For a pneumatic impact wrench, attach a well-lubricated air hose with the correct pressure from your compressor. For an electric impact wrench, plug it into a grounded outlet. For a battery impact wrench / cordless impact wrench, ensure the battery is fully charged and locked in place.

- Fit the socket securely on the square drive. Typical impact gun sizes include 3/8″, 1/2″ and 3/4″ drives. Choose the one that matches your fastener size and torque needs.

How to Use an Impact Wrench

Once your impact wrench is set up, follow these steps to operate it safely and effectively:

- Position the socket correctly. Slide the impact-rated socket fully over the fastener; a loose fit can round off nuts.

- Brace yourself. Even a mid-sized high torque impact wrench can deliver a sudden jolt. Hold it with both hands when possible.

- Trigger control. Squeeze the trigger lightly at first to spin up the motor, then let the hammer-and-anvil mechanism deliver its impacts.

- Use short bursts. Especially when tightening, pulse the trigger and check the torque to avoid overtightening.

Troubleshooting: Impact Wrench Not Working

Even the most premium wrenches can run into issues. Here are the common problems and how you can fix them:

Problem: Weak impacts or no hammer action.

How to troubleshoot:

- Check the power source to ensure adequate compressor pressure for pneumatic models or fully charged batteries for cordless wrenches.

- Clean and lubricate regularly to maintain performance.

- Avoid over-torquing bolts to prevent strain on the mechanism.

Problem: The battery impact wrench loses power quickly.

How to troubleshoot:

- Test battery health and replace it if the voltage drops rapidly.

- Prevent overheating, and allow the tool and battery to cool during extended use.

- Keep spare batteries charged and rotate usage to minimize downtime.

Problem: Stuck socket or drive

How to troubleshoot:

- Ensure proper fit: use impact-rated sockets matching the drive size (3/8″, 1/2″, 3/4″).

- Lightly oil the drive connection to prevent jamming.

- Never force a stuck socket to avoid rounding fasteners or damaging the tool.

Why an Impact Wrench Is Worth Having

It helps you save time with tasks like replacing suspension components or just changing all four tires can be accomplished in a matter of minutes, rather than using a hand tool that could take hours. Additionally, you get a variety of sizes of impact guns; either a 3/8″ for lighter work, a 1/2″ for general automotive, or 3/4″ and 1″ for heavy-duty.

However, it can be quite loud and may require hearing protection during long, continued use. Also, if you are not careful and use proper technique, it is possible to over-torque fasteners without a torque wrench.

Professional-Grade Impact Wrenches from MAXXT-Tech

For professional and serious DIYers who demand reliability, MAXXT-Tech offers a full line of pneumatic, electric and cordless impact wrenches that are specifically made for high torque, long life and ergonomic comfort. So if you are in need of a lightweight 3/8″ which is for more precision work or a 1” drive beast, which is perfect for industrial bolts, MAXXT-Tech tools are made exactly for that! Make sure to check our professional impact wrench range to find the ideal impact wrench for your shop or mobile kit, and pair it with the proper sockets, air accessories and torque wrenches for a full fastening solution.

Conclusão

An impact wrench is more than just a convenience tool; it’s a force multiplier for anyone who is dealing with heavy fasteners. You have learned what an impact wrench is, how it functions, different types, how to set it up, how to use it, and what to do for its longevity.

So if your choice is for a pneumatic impact wrench for your garage, an electric impact wrench for your bench, or a battery impact wrench for mobility, having their understanding of its strengths and limits sets you to work faster, safer, and smarter. And once you are ready for those tools, brands such as MAXXT-Tech deliver the precision edge.

Perguntas frequentes

What Size of Impact Wrench Do I Need?

The best size of impact wrench for you depends on the size of the fasteners you use most often. 3/8″ drive: Light work, small bolts, and precision work. 1/2″ drive: General automotive, and most lug nuts and suspension bolts. 3/4″ or 1″ drive: Heavy industrial or construction bolts.

Can You Use a Torque Wrench to Loosen Bolts?

A torque wrench is a tool that is used to tighten a fastener to a specific torque; it is not used to loosen fasteners that are stuck. Using a torque wrench as a breaker bar to loosen a fastener may damage the torque wrench and give you incorrect torque readings.

How Do I Maintain and Safely Use an Impact Wrench?

- Lubricate regularly

- Keep batteries conditioned.

- Use proper sockets and accessories.

- Wear PPE.

- Store properly