Оглавление

ПереключатьYou finally set aside time to sand down that old cabinet or wooden chair. You start working, but something feels off. The finish isn’t smooth, and the corners are still rough. Most of the time, this happens because the wrong type of sander was used for the job.

Not all sanders work the same way. Some are better for speed, while others are better for fine details. If you’re unsure which one to pick, you’re not alone. Many people don’t know the difference between an orbital sander and a sheet sander.

This guide will explain what sets these two sanders apart. You’ll learn how each one works, what kind of projects they’re best for, and how to choose the right one for your needs. By the end, you’ll feel more confident choosing the right tool, whether you’re sanding a large surface or working in a tight corner.

Understanding Orbital and Sheet Sanders

Before you choose a sander, it helps to understand how each type works. Orbital sanders and sheet sanders may seem similar, but they move differently and are built for different kinds of tasks.

Что такое орбитальная шлифовальная машинка?

An orbital sander has a round sanding pad that moves in tiny circles. This motion is called “orbital” because it spins in random patterns. That’s why it’s often called a “random orbital sander.”

Orbital sanders are usually used for smoothing large, flat areas. The random motion helps reduce swirl marks and gives a smooth finish. Many models also come with dust collection systems, which makes cleanup easier.

There are a few types of orbital sanders:

- Random orbital sanders are the most common. They work fast and are great for general use.

- Electric orbital sanders plug into the wall and give steady power for longer jobs.

- Large orbital sanders are heavier and used for sanding big surfaces like floors.

What Is a Sheet Sander?

A sheet sander uses a square or rectangular pad. It holds a piece of sandpaper and moves it back and forth in straight lines. This is called a vibration or linear motion.

Sheet sanders are great for light sanding and finishing work. Because of their flat shape, they are easier to use in corners and along edges. They are also lightweight and easy to control.

Some people call them “finishing sanders” because they are often used at the end of a sanding project to smooth out small spots.

If you’re comparing different sander designs and wondering which specific models suit your workload and budget, Best Sanders for DIY Enthusiasts of 2025 gives a practical overview of the latest options and who they’re best for.

Now that you know the basics, let’s look at how these sanders compare in performance, cost, and results.

Orbital vs Sheet Sanders: Key Differences

Although orbital and sheet sanders are both used for sanding, they work in different ways and are better suited for different tasks. Here are the main differences to help you decide which one is right for your project.

| Особенность | Орбитальная шлифовальная машина | Листовой шлифовальный станок |

|---|---|---|

| Motion | Circular/random | Straight-line vibration |

| Качество отделки | Smoother on large surfaces | Better for corners and edges |

| Speed | Faster material removal | Slower, more precise |

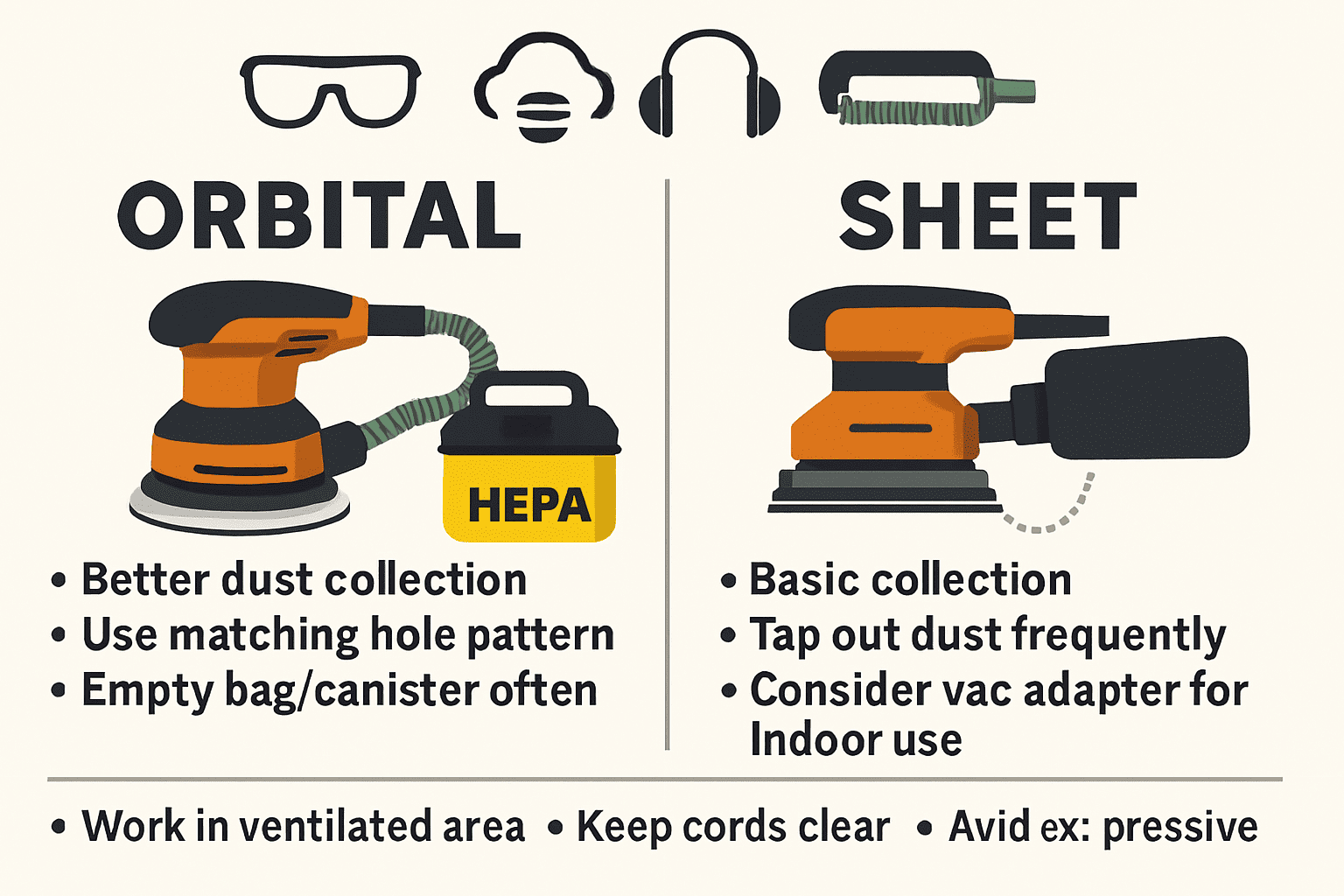

| Dust Collection | Usually better | Often basic |

| Sandpaper Type | Round discs (hook-and-loop) | Cut sheets (clip-in) |

| Cost of Sandpaper | Higher | Lower |

| Best For | General sanding, paint removal | Fine finishing, tight spaces |

Pros and Cons of Each Type

Knowing the strengths and weaknesses of each sander can help you decide which one fits your work style and project needs. Below is a closer look at what each tool does well and where it might fall short.

Orbital Sander: Pros and Cons

Плюсы:

- It removes material quickly, which saves time on large or rough surfaces.

- It gives a smooth finish with fewer visible marks, especially when used with the right grit.

- Most models have good dust collection, which helps keep your workspace cleaner.

- It works well on flat areas like tabletops, doors, and wooden panels.

Cons:

- It is usually more expensive than a sheet sander, both for the tool and for the sandpaper discs.

- It doesn’t work well in tight corners or along straight edges.

- The round pad can miss spots near walls or corners.

Sheet Sander: Pros and Cons

Плюсы:

- It costs less and uses regular sandpaper, which is cheaper and easier to replace.

- The square or rectangular shape makes it easier to sand in corners and along edges.

- It is lightweight and easy to control, especially for beginners or fine work.

- It is great for finishing sanding, such as between coats of paint or varnish.

Cons:

- It removes material slowly, so it’s not ideal for tough jobs like stripping old paint.

- If you move it against the grain or press too hard, it can leave straight-line marks.

- Dust collection is not always as effective as with orbital models.

When to Use Each Type

Both orbital and sheet sanders can be useful, but the right one to choose depends on the task. Some jobs need power and speed, while others require precision and control. Let’s look at when each type works best.

When to Use an Orbital Sander

Use an orbital sander when:

- You need to remove paint, varnish, or old finishes from large, flat surfaces.

- You are sanding rough wood to create a smooth base.

- You want to prepare a surface for painting or staining.

- You are working on projects like doors, tabletops, shelves, or furniture panels.

Orbital sanders are also helpful for sanding between coats if you use a fine grit. They are fast and cover a lot of space in less time.Orbital sanders are especially useful when you’re stripping or refinishing tabletops, doors, or other flat furniture surfaces as part of a restaining project. For a practical, step‑by‑step walkthrough of that process, How to Restain Wood Furniture shows how sanding fits into the full refinishing workflow.

When to Use a Sheet Sander

Use a sheet sander when:

- You need to sand inside corners, along edges, or in small spaces.

- You are finishing a surface and want to avoid removing too much material.

- You are sanding between coats of paint or finish on cabinets or trim.

- You are working on projects like dressers, drawers, chairs, or cabinet doors.

Sheet sanders give you more control. They are gentle and good for detailed work or final sanding passes.

Suitability for Different Materials

- Wood: Both sanders work well. Use an orbital for heavy sanding, and sheet for finishing.

- Metal: Orbital sanders work better on metal because they can remove rust or paint quickly. Use fine-grit discs to avoid scratching the surface.

- Plastic: Sheet sanders are safer on plastic, especially if you’re working on thinner parts. Orbital sanders may melt or gouge plastic if used with too much pressure or speed.

Sandpaper Grit Guide: Choosing the Right Grit

The type of sandpaper you use matters just as much as the sander itself. Here’s a simple grit guide to help you choose the right one based on your sanding goal:

| Grit Range | Use Case |

|---|---|

| 40–60 (Coarse) | Heavy material removal, paint/varnish stripping |

| 80–100 (Medium) | General-purpose sanding on raw wood |

| 120–150 (Fine) | Surface prep before finishing (paint or stain) |

| 180–220 (Very Fine) | Final smoothing, sanding between coats |

| 320+ (Extra Fine) | Polishing or ultra-smooth finishing on delicate surfaces |

Always start with a lower grit for rough surfaces and move up gradually to avoid scratches and get a smooth finish.

How to Use Each Sander Properly

To get smooth, even results, it’s important to use your sander the right way. Each type of sander has its own technique. Using them correctly helps avoid scratches, swirl marks, or uneven finishes.

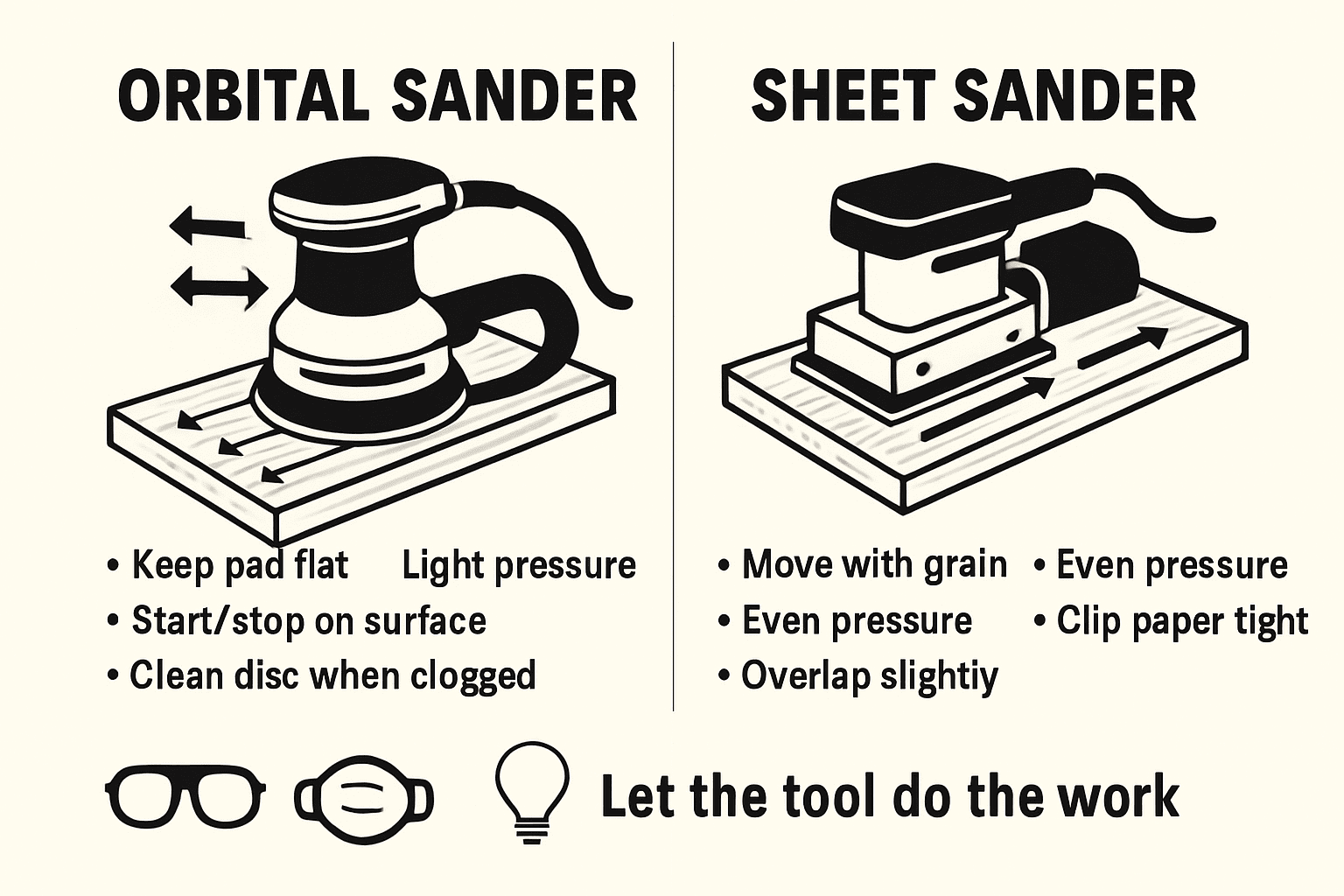

Using an Orbital Sander

Prepare the surface

Make sure the surface is clean and dry. Remove any loose dirt or debris before sanding.

Choose the right grit

Start with a coarse grit (like 80 or 100) if you need to remove material. Switch to finer grits (such as 180 or 220) for finishing work.

Attach the sanding disc

Use the correct size and hole pattern for your orbital sander. Make sure it sticks firmly using the hook-and-loop system.

Hold it flat and apply light pressure

Place the sander flat on the surface. Turn it on while it’s already touching the surface to avoid making marks. Let the tool do the work because pressing too hard can leave micro-scratches.

Move slowly and evenly

Sand in a slow, overlapping pattern. Avoid staying in one spot for too long, as this can leave uneven areas.

Keep the pad clean

Wipe the sanding pad or switch to a fresh disc if it gets clogged.

Wear safety gear

Use safety glasses and a dust mask, especially if you’re sanding paint or working indoors.Using a Sheet Sander

Cut and attach the sandpaper

Use standard sandpaper sheets and cut them to fit your sander. Clip the paper tightly into the sander so it doesn’t slip.

Choose the right grit

Like with orbital sanders, start with a lower grit to remove more material and move to finer grits for a smooth finish.

Sand with the grain

Always move the sander in the same direction as the wood grain. This helps avoid scratches and leaves a cleaner look.

Hold it evenly

Keep steady pressure and make sure the full pad stays in contact with the surface.

Work in small sections

Move the sander in long, even strokes. Overlap each pass slightly for a uniform finish.

Clean or change paper as needed

If the sandpaper gets worn or clogged, replace it. This helps keep your sanding smooth and efficient.

Learning the proper way to use each sander will help you avoid common mistakes.

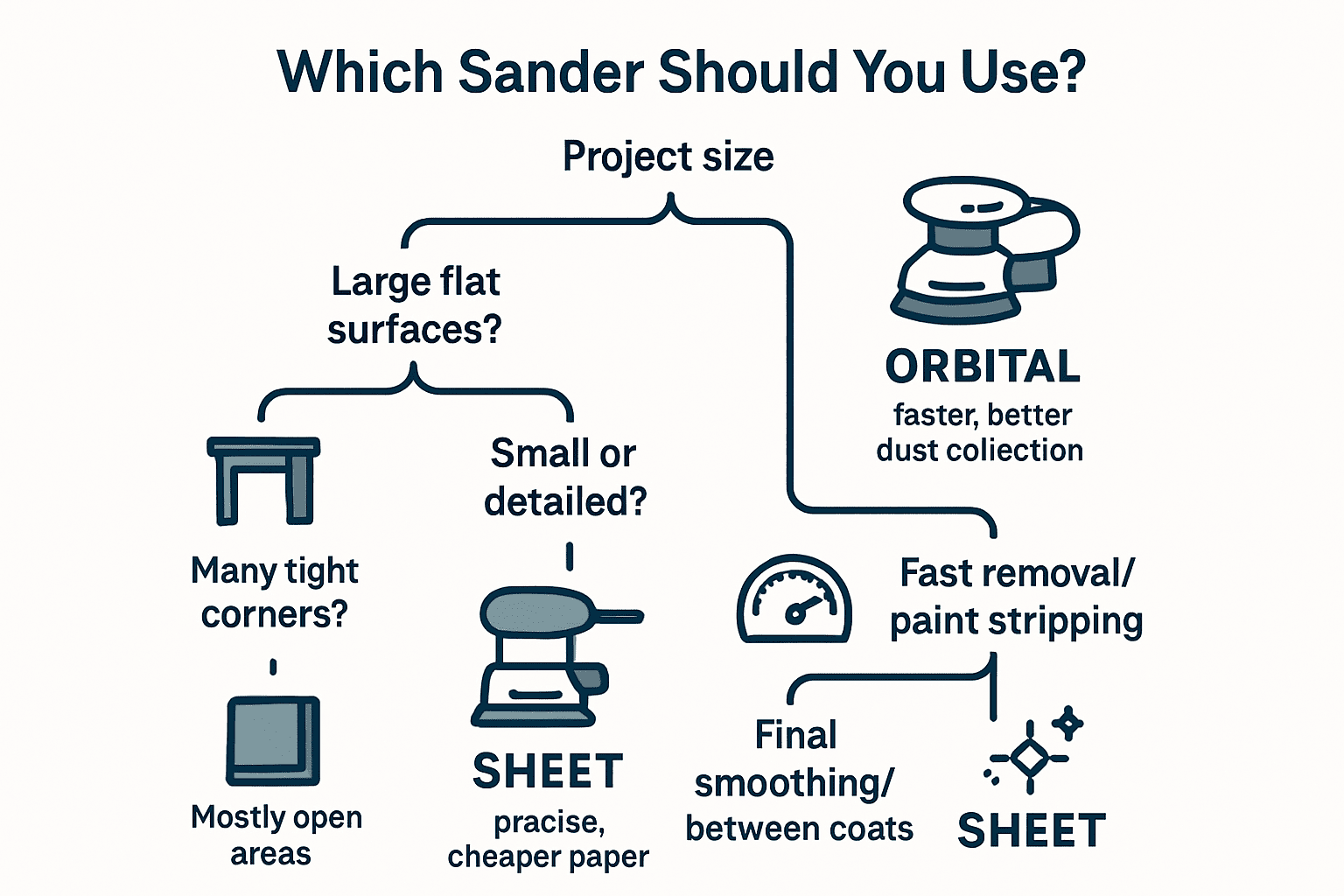

Choosing the Right Sander for Your Project

The best sander for your project depends on what you are sanding, how smooth you want the finish to be, and how much time you want to spend. Let’s break it down to help you choose the right tool.

Think About the Type of Project

- If you are sanding large, flat surfaces like tabletops, doors, or shelves, an orbital sander is usually the better choice. It covers more space quickly and gives a smooth finish.

- If you are sanding furniture with corners, edges, or small details like dressers, cabinets, or chairs, a sheet sander gives you better control and can reach tighter areas.

Consider the Finish You Want

- For rough surfaces or for removing paint or stain, go with an orbital sander. It removes material quickly and helps smooth out uneven areas.

- For light sanding or a final pass before painting or sealing, a sheet sander is better. It’s gentle and helps create a clean, even surface.

Look at Surface Size and Detail

- Large surfaces: Orbital sander

- Tight corners or edges: Sheet sander

- Curved or detailed pieces: You might even need a small detail sander

Budget and Long-Term Use

- Sheet sanders usually cost less up front and use standard sandpaper, which is cheaper.

- Orbital sanders may cost more, but they work faster and offer better dust control, which can save time and effort on bigger projects.

Sandpaper Cost Comparison

- Орбитальные шлифовальные машины use circular discs that often cost more and must match the size and hole pattern of your tool.

- Листовые шлифовальные машины use standard rectangular sandpaper, which is cheaper and easier to find. You can even cut sheets from full-size sandpaper to save money.

If you do a lot of general sanding and want something fast and flexible, an orbital sander is a great pick. If you need more precision or do a lot of finish work, a sheet sander may be the better choice.And if sanding is just one part of a broader woodworking setup you’re planning, Essential power tools for woodworking gives a bigger‑picture view of which machines most shops and serious DIYers rely on alongside their sanders.

Who Should Use Which? (DIY, Professional, B2B)

Different users have different needs. A casual DIYer won’t use a sander the same way a cabinet maker or a contractor would. Here’s how to decide which sander fits best depending on who you are and how often you use the tool.

DIY Homeowners

If you’re handling small home projects like sanding a table, fixing a door, or prepping a surface for paint, an orbital sander is usually the better option. It’s fast, easy to use, and works well for most general tasks. However, if your project involves corners or edges, keeping a sheet sander on hand is helpful too.

Best fit: Orbital sander for general use, sheet sander for finishing and edges.

Furniture Makers and Hobbyists

If you often work on furniture or smaller wooden items, a sheet sander is a smart choice. It allows you to sand detailed areas, corners, and between tight spots without removing too much material. You can also pair it with an orbital sander for larger areas.

Best fit: Sheet sander for control, orbital sander as a secondary tool.

Professionals and Contractors

Professionals often need tools that are fast, reliable, and durable. If you work on big projects, need to remove material quickly, or have tight deadlines, an orbital sander is more efficient. For fine finishing or sanding between coats, a sheet sander is still useful.

Best fit: Orbital sander for power and speed, sheet sander for fine work and detail sanding.

Industrial and B2B Users

In industries like cabinet manufacturing or flooring, the choice depends on the task. Teams may use both tools side by side. Orbital sanders handle most of the heavy work, while sheet sanders are used during final finishing steps or in hard-to-reach areas.

Best fit: A combination of both, depending on the workflow.

No matter your skill level, choosing the right sander helps you work smarter, not harder.

Sander Care and Maintenance

Keeping your sander in top shape ensures better results and a longer tool life. Here are some care tips:

- Clean the pad regularly: Dust buildup can reduce performance and cause uneven sanding.

- Empty the dust collection system: Don’t wait for it to clog, empty it after each session.

- Check the power cord or battery: Look for frays or signs of wear to avoid power issues.

- Replace worn pads and clips: If the hook-and-loop pad or sheet clamps are loose, replace them to maintain sanding efficiency.

- Store in a dry place: Moisture can damage electrical components or cause rust.

A little care after each project helps your tool stay reliable and effective.

Conclusion: Choose the Best Sander for Your Needs

Choosing between an orbital sander and a sheet sander comes down to your project needs, your skill level, and how much control or speed you want.

Orbital sanders are great when you need to work quickly on large, flat surfaces. They’re versatile, powerful, and give a smooth finish with less effort. On the other hand, sheet sanders are better for smaller, more detailed jobs. They give you more control and are easier to use in corners and along edges.

Both sanders have their pros and cons, and in many cases, using both on the same project gives the best results. For example, you might use an orbital sander to remove an old finish, then switch to a sheet sander for final smoothing.

Also, don’t forget to think about long-term costs. Orbital sanders may cost more at first and need specific sanding discs, but they save time on big jobs. Sheet sanders cost less and use regular sandpaper, which is more affordable and widely available.

In the end, the right choice depends on what you’re building, fixing, or finishing. Take a few minutes to think about your project before buying a tool. A well-chosen sander can save you time, money, and frustration in the long run.

To dive deeper into proper sanding techniques, check out our blog on how to use an orbital sander or browse the latest MaxXT sander tools.

Safety Precautions When Using Sanders

While sanders are relatively safe tools, proper usage is key to preventing accidents and maintaining a safe workspace.

- Wear protective gear: Always use safety glasses, a dust mask, and hearing protection.

- Secure your workpiece: Make sure the item you’re sanding is stable to avoid slips or kickbacks.

- Don’t press too hard: Let the tool do the work because excess pressure can damage both the tool and the surface.

- Disconnect before changing sandpaper: Always unplug or remove the battery before swapping sanding pads or making adjustments.

- Use in a ventilated area: Sanding generates fine dust that can irritate lungs that is why good airflow is essential.

- Watch cords and cables: Keep power cords out of the way to avoid tripping or cutting them accidentally.

A few basic safety habits go a long way in protecting you and your tool.

Часто задаваемые вопросы

1. What is the main difference between orbital and sheet sanders?

The main difference is how they move. Orbital sanders move in small, random circles, while sheet sanders move in straight lines. This affects how fast they work and the kind of finish they leave behind.

2. Is a random orbital sander better than a sheet sander?

It depends on the job. A random orbital sander is better for removing material quickly and getting a smooth finish on flat surfaces. A sheet sander is better for fine work and getting into corners or edges.

3. Can you use a sheet sander for furniture refinishing?

Yes, a sheet sander works well for furniture. It is gentle and gives you more control, especially on detailed pieces or corners.

4. Do orbital sanders leave swirl marks?

They can leave swirl marks if you press too hard or use the wrong grit. However, when used correctly, they usually give a very smooth finish.

5. Can I use a sheet sander on wood floors or large panels?

You can, but it will take longer. A sheet sander works best for smaller areas or finishing touches. For large surfaces like floors, an orbital sander is faster and more efficient.

6. Which sander is best for cabinets and tight corners?

A sheet sander is the better choice for cabinets and corners. Its flat shape and straight edges make it easier to reach into small or narrow areas.

7. How much does a good orbital sander cost?

A quality orbital sander usually costs between $50 and $150, depending on the brand, power, and features. Some professional models may cost more.

8. Can a circular sander be used for polishing too?

Yes, some orbital sanders can be used for polishing if you attach the right pad and use a polishing compound. However, they need to be handled carefully to avoid damaging the surface.

9. What’s the best beginner-friendly sander?

A random orbital sander is a good choice for beginners. It’s easy to use, works on many surfaces, and is less likely to leave marks if used properly.

10. Can I use both sanders on one project?

Yes, many people use both. You can use the orbital sander to remove material quickly and the sheet sander to finish edges or tight spots. This gives you the best of both tools.